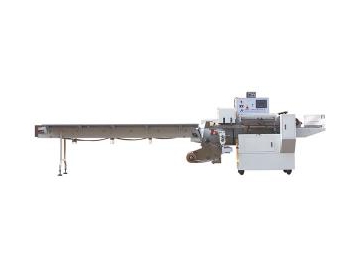

Automatic Multi Servo Driven Horizontal Packing Machine

Horizontal Packaging Machine, Horizontal Flow Wrapper, Servo Assisted Horizontal Wrapping Machine, Servo Driven Flow Wrapping Machine

The main machine adopts at least two sets of servo motors to respectively control horizontal sealing and film feeding system. Equipped with 10” touch screen, different products’ packing can be realized by changing the parameters of cutting length and the relative position between cutter and pushers. The cutting position can be set or revised directly on the touch screen, realizing a highly automatic manipulation.

Back sealer adopts three pairs of sealing wheels to ensure high sealing strength. With the pneumatic open-close device, the back sealing wheels will open while machine stops to avoid film burnt wastage.

The product feeding conveyor is driven by individual servo motor, and the chain runs stably inside the nylon guide rail. The food packing machine is equipped with auto splicer so the film can be spliced automatically while the machine is running at high speed.

The whole packing machine adopts open cantilever structure and synchronous belt drive method, ensuring easy maintenance, low noise and smooth running. High expansibility of the packing machine enables it to be connected with various automatic feeding systems.

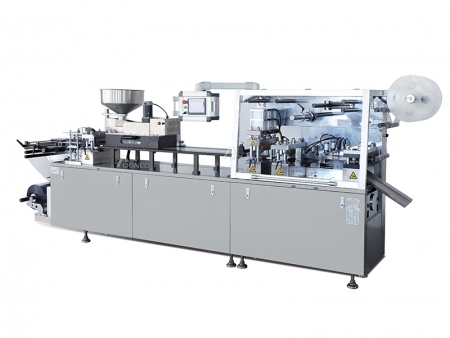

Apex provides two variants of control systems for BJWE series machines. One type features motion control, and PLC control for the others.

Three or more servo motors are appropriate for packing machines with motion control system. Electronic cam function is available to replace the traditional mechanical eccentric mechanism. The electronic cam contributes to guarantee the packing speed,the flexibility and the packing range. Also, it can provide empty packing detection and electronic anti-cut functions.

Empty packing detection: the cutting roller and the filming roller will stop at the horizontal position when there is an empty pack, while the conveyor will keep running. If the empty packs happen to be delivered continuously from the conveyor, the machine will stop automatically and send an artificial feeding signal.

Electronic anti-cut: the packing machine will detect the dislocation or wrong dimension phenomenon and stop cutting when the wrong pack arrives. If faults occur continuously, it will remind the operators to check the feeding position automatically (not suitable for packing materials with aluminum foil or aluminized film).

PLC control machine still uses traditional mechanical eccentric mechanism. 3 servo motors are suggested for it.

You can contact us for a quotation or with any questions you may have on this product.