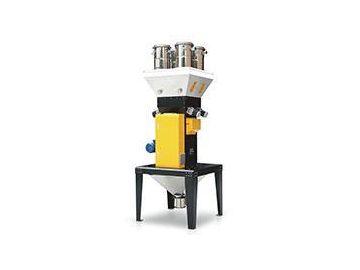

Gravimetric Yield Control Resin Blender

Application

The gravimetric yield control resin blender is used for the transportation of plastic granules, powder, calcium carbonate, talc powder, resin film powder, flour, starch and other raw materials. Aiming for different raw materials and their needs, we have designed two different scale bodies: a powder scale (which solves the problems of feeding and metering with a poor fluidity) and a granular scale (which solves any possible bridging problems).

Features

1. The original mechanical parts of the gravimetric yield control resin blender, such as the screw, are easily disassembled, so that it is easy to assemble, and clean.

2. The feeding performance is stable with a high precision and optional large range conveyance capacity.

3. The control system of the gravimetric yield control resin blender achieves manual and automatic control feeding and feed supplement, as well as manual and automatic conversion, making the control system flexible.

Main configuration

- Material collector

- Thermal insulated transition hopper

- Weightless scale

- Console

- Feeder

Equipped with SIEMENS electronic components, operation is stable.

The material collector can run independently with stable operation and a low failure rate. It can also be equipped with a central material conveyance system, which is an indispensable component of material transportation.

Features

1. The collector can open the cover directly without the need to disassemble the cable and the vacuum pipeline, making the equipment easy to clean.

2. Gravity balance design, perfect sealing performance.

3. High performance magnetic sensor with long service life and high reliability.

It is used to store the dried material and installed at the material entrance of the molding machine. The inner cavity is smooth in order to facilitate easy material falling, and with specifications ranging between 15 to 100L, it is able to meet various output demands.

Pure stainless steel manufacturing, no material pollution

Pure stainless steel manufacturing, no material pollution  Thickened 40MM asbestos insulation layer, greatly locks the heat and prolongs the heat preservation time

Thickened 40MM asbestos insulation layer, greatly locks the heat and prolongs the heat preservation time

The HF feeder series is equipped with a highly efficient vacuum pump with a delivery capacity of up to 1200 kg/h, a maximum conveying distance of 100 meters, and equipped with cylinder filter that is tightly structured and combines a cyclone effect with dust separation. This makes it suitable for the delivery of dusty materials.

Features

1. Maintenance free motor, convenient filter core cleaning.

2. Noise level is lower than 78DB (A)

3. Vertical design scheme, small covering area.