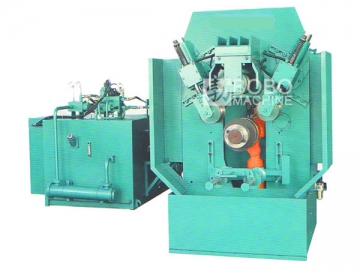

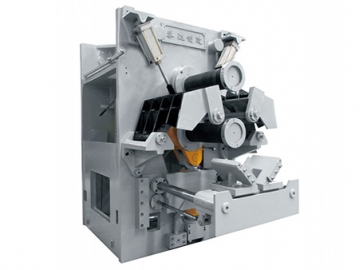

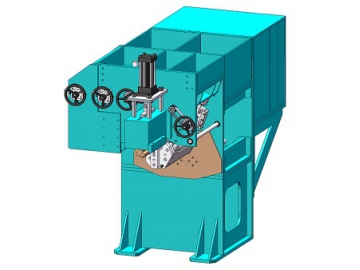

Wheel Roll Forming Machine

The wheel roll forming machine forms the section profile of the tubeless wheel rim. Three sets of machines usually operate in unison to form the wheel rim in a sequential manner that delivers the final profile. Rotary roll forming is a cold forming process where straight side cylinders or rings are utilized to form profiles. The blank is roll formed between the upper and lower dies mounted on two horizontal spindles. The rim profile gradually forms through a three-step process while the dies and the blank are rotated simultaneously in a predetermined path alongside the guiding roll. The roll formers are powered by a hydraulic motor driving system that allows for automatic speed synchronization and ideal torque distribution between the upper and lower dies. A loader and un-loader are implemented to handle the blank.

Technical Specifications

| Diameter range of wheel rim | 17.5" ~24" |

| Width of wheel rim | 7.7" -11" |

| Thickness of material | 5-10mm |

| Diameter of top roller | ¢2350-0.02 |

| Diameter of bottom roller | ¢1450-0.02 |

| Central distance between two rollers | 362mm ~462mm |

| Clamping force | 10000kg |

| Productivity | About 3 pics /min |

| Spindle speed (bottom roller) | 340 rpm |

| Control system | PLC |

| Power | 105KW |

| Dimension | 2000X2600X2400mm |

| Weight | About 10ton |

As a specialized wheel roll forming machine manufacturer in China, we at BOBO Machine also provide PU Foam Injection Machine, flexible hose machine, corrugated pipe machine, waste paper baler, and much more.