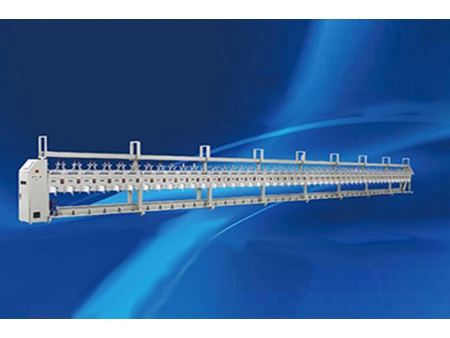

GH018-S High-Speed Soft Winding Machine

Request a Quote

GH018-S High-Speed Soft Winding Machine

GH018-S high speed soft winding machine is used before dying to wind yarns from cones to cones and to achieve a soft winded package with a good density. The winding speed can be automatically controlled by the computer, with a max. speed up to 1100 m/min. It is an ideal winder for cotton, silk and chemical fiber yarns.

Technical Parameters

| Grooved drum | O/D 82mm, lead 2.5(turns)×147, angle: 0° |

| Take-up tubes | Cylindrical (0°)/cones with a conicity of 3°30′, 4 °20′ |

| Bobbin length | Standard 170mm, customized range: 170-280mm |

| Yarn length control | Electronically set the winding yarn length up to 999999 m according to the final package. |

| Slow start | Ensures a slow and stable start to improve the winding quality. |

| Counterweight yarn brake | Prevent the yarn from shaking during the feeding to provide suitable winding tension. |

| Knot clearing adjuster | Adjust the clearing gap |

| Electronic tensioner | Tension plate |

| Number of spindles per section | 12 per section |

| Number of spindles, max. | 120 |

| Drive | Individual variable frequency motor per spindle |

| Max. winding linear speed | 1100 m/min, individually controlled per section, frequency control |

| Traverse | Standard: 147mm, 152mm |

| Creel balancer | Winding tension is controlled by a spring balancer |

| Yarn detector | Photoelectric sensor |

| Package diameter | Max. 280mm |

| Start/Stop | Membrane switch control, touch screen |

| Vertical anti-patterning device | Computer controlled |

| Vacuum cleaner/blower | Optional, 1100W (cleaning power) |

| Power consumption | 60W/spindle (at the highest speed), including the power of cleaner motor |

| Power supply | 3-phase 380V 10% , 50/60Hz;220V; 440V |

| Weight (12 spindles) | 350kg |

| Dimension (12 spindles) | 2250mm (L)×1100mm(W)×1400mm(H) |

| Cleaner weight | 132 kg, depending on the number of spindles |

| Weight and dimension of the electricity box | 45kg, 700mm(L)×300mm(W)×1320mm(H) |

Main features

- Advanced yarn cleaning, tension control device and photoelectric yarn detecting avoid the yarn loop.

- Accurate and sensitive speed sensor ensures consistent winding length and package weight.

Advantages

- Durable metal arbor support

- Easy opening central positioning structure of the bobbin holder offers the ease of removal of the winded package.

- Yarn inlet/outlet is equipped with ceramic protection to avoid affecting the yarn quality by friction.

- The grooved drum has dust-proof and anti-twisting device to avoid the dust accumulation and to protect the rolling bearing.

- Double-sided spindle layout comes with 12 spindle per section. Maximum number of spindles is 120 pcs of 10 sections per machine.

- Rotating pin and counterweight yarn brake offer flexible control of winding tension.

- Spring holder pressure balancer ensures uniform winding density during the whole winding process.

- Horizontal traverse soft edge device ensures even dying possible for soft packages.

- Photoelectric length measuring device ensures the winding length of each spindle is accurately consistent.

Details

Leave a Message

Related products

Send Message

Most Recent

More

Other Products

Videos