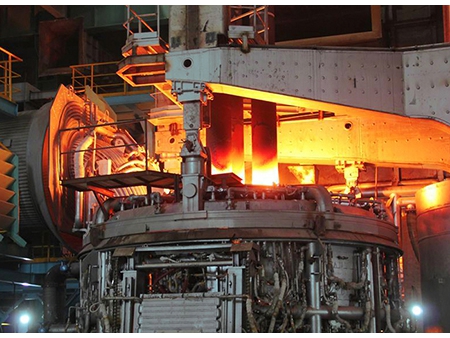

Electrode Regulation for Electric Arc Furnace (EAF-ER)

Used for: AC Electric Arc Furnaces, DC Electric Arc Furnaces, Ladle Furnaces, Submerged Arc Furnaces, Arc Cracking Furnaces.

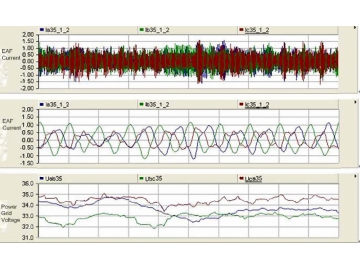

The RXPE furnace electrodes regulator (FER) is designed with a constant electrode admittance control strategy. This is achieved via fast & accurate instantaneous active power and reactive power calculations, based on an instant d-q var algorithm and FFT algorithm. The regulator uses this strategy to control the furnace during real time three phase admittances, ensuring the three-phase power of the furnace results in less impact and influence to the connected power grid as well as enhancing productivity, saving energy, and decreasing electrode consumption.

The RXPE furnace electrodes regulator (FER) is not only designed to achieve stable electrode adjustment; but it is also designed to combine with the furnace reactive power compensation system (RXPE SVCs) through high-speed optical communication interfaces, resulting in even smarter electrodes adjustment, even more efficient smelting processes, and much better var compensation effects. This helps improve the smelting efficiency and reduce power grid impacts.

Smoother control of the furnace electrodes with less impact on power grids during smelting processes.

The RXPE furnace electrodes regulator (FER) is designed with state-of-the-art high-speed processors (DSP/FPGA), rather than the traditional design programmable logic controllers (PLC), resulting in an improved electrode regulator calculation speed and response time. Furthermore, an advanced instantaneous reactive power control strategy is utilized rather than a traditional power-frequency based cycle-level computing strategy. With this software control innovation, during the furnace boring stages and melting stages, when raw materials collapse occurs, if the electrodes touch raw materials or dip into the liquid pool, electrodes are lifted much faster. By doing so, furnace electrode responses are faster, the arc voltage and arc current is much more stable, the impact to power grids is significantly less while smelting, and the three-phase unbalances and flicker severity will be significantly mitigated.

- Improved EAF smelting efficiency

With the use of RXPE’s furnace electrodes regulator (FER), furnace smelting operations are much more stable under the same operating process. Arc extinguishing cases will be significantly reduced, ensuring the average input power has been significantly improved, which then results in a much shorter smelting time and improves smelting efficiency.

- Reduced electrodes consumptions

With the use of RXPE’s furnace electrodes regulator (FER), the electrode lifting response speed is greatly improved, which effectively reduces electrode breakage and accidents, as well as prevents electrodes from dipping into the liquid pool to reduce electrode consumption and save smelting costs.

Reserved data interface for furnace var predictions, aiming for improved response speed when integrated with furnace reactive power compensators.

The RXPE furnace electrodes regulator (FER) provides the output the target value of three-phase instantaneous reactive power demands for electric arc furnaces, while achieving stable electrode adjustments. Such target var demands can be utilized for fast control of the furnace reactive power compensators. Compared to conventional reactive power compensation methods, this solution introduces an advanced observation to furnace reactive power demands, and as a result, improves dynamic reactive power compensator compensation speeds. It improved the furnace var compensation effects, and significantly reduced the furnace impacts to power grids.