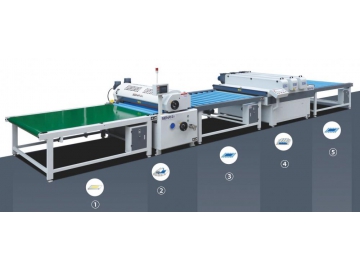

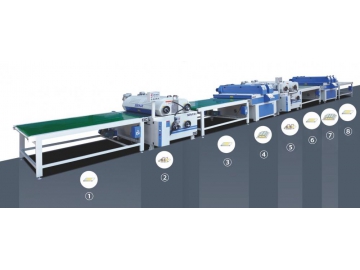

Roll Coater Type SC-CCP120, Ceramic Transfer Paper Coating Drying Line

SC-CCP120 ceramic transfer paper coater is a newly developed coating machine. It is mainly used for roll coating on ceramic transfer paper, kraft paper, coated paper, etc.

This roll coater adopts anilox roll with engraved pattern, which applies coating on webs with four times on front side and one time on backside. Equipped with advanced automatic control technical and drying system, multiple processes can be finished in one operation, including web unwinding, receiving, coating, drying, secondary coating, secondary drying, calendering, rewinding.

Specifications

Machine speed: 120m/min

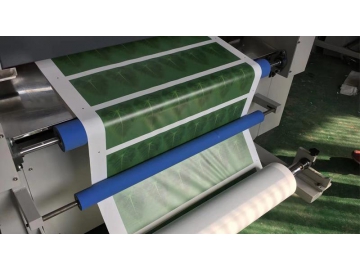

Coating method: anilox roll, coating four times on front side and one time on backside of web

Coating substrate: paper 100-170g/㎡, thickness: 12μ-30μm

Coating thickness: 25-30μm

Tension range: 200-600N/full width

1. Reversible independent turret unwinding with dual-shaft double working positions.

2. Edge position control (EPC) for automatic web guiding.

1. Anilox roll is used in coating process, driven by independent inverter motor with gear coupling.

2. With back-up roll and smooth roll, simultaneous tension is controlled by PLC system.

1. Calender roll has a hard chrome plated surface, and treated with mirror polishing. The maximum pressure force reaches 3000Kg/full width which is adjustable. Steel back-up roll is equipped.

2. Cooling roll is made of hard chrome plated steel, the cooling method of which is circulating water cooling.

1. Reversible independent turret rewinding with dual-shaft double working positions.

2. AC variable frequency drive with closed loop vector control, and PLC system for automatic taper tension control.

1. Horizontal and vertical drying chambers.

2. Drying tunnel is designed with insulating layer.

3. Hot air nozzle has maximum flow speed of 25m/sec.

4. Drying chambers are opened and closed pneumatically.