Vertical Form Fill Seal Machine (VFFS)

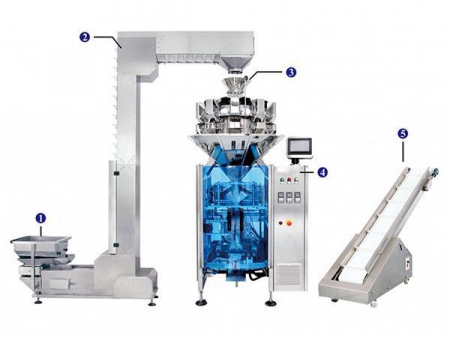

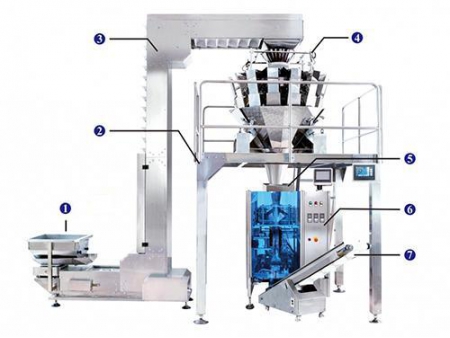

The vertical form fill seal machine is driven by a dual servo motor and is able to fully control acceleration, deceleration and positioning. The maximum production speed reaches 100 bags per minute. With a convenient operation, the vertical form fill seal machine has a standard configuration of stainless steel or carbon steel machine structure (selective assembly), vacuum pull bets for easier control on thin metallized films as well as a hinged electrical enclosure. Either side of the bagging machine is able to connect with other equipment.

Applicable packing products: All types of snacks, frozen foods, pet foods, puffed foods, medicinal materials, hardware and more

Applicable bag types: Pillow bags, gusset bags, euro slot bags and more

Applicable film materials: All types of composite films, single layer PE film

Applicable film thickness: 0.04mm-0.15mm

- Control: Uses a PLC control panel that allows for malfunction display, malfunction alerts, and a protective stop function whenever the door is opened.

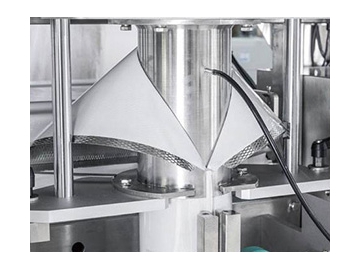

- Bag forming: Automatic vertical bag forming.

- Bag filling and sealing: Both the vertical and horizontal sealer bar is driven by an air cylinder, and carries out bag sealing via a continuous heating. The vertical form fill seal machine can make sealed bags (the system will stop automatically if the sealing bars clamp on the products) or reopen bags with a sticker/clip.

- Film tension: Driven by servo motor to adjust the tension on film transportation. This ensures the bag forming consistency.

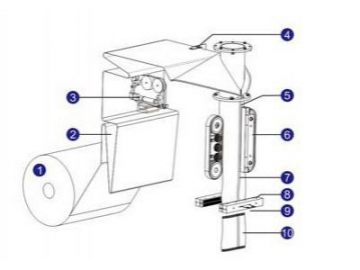

- Film transport & unwind: Uses an air-expansion of the mechanical film shaft, and is equipped with label printing adjustment, color code tracking adjustment, and auto alert without feeding.

- Machine structures: Stainless steel or carbon steel structure (selective assembly).

① Film roll

② Film tightening

③ Label printing

④ Color code tracking

⑤ Forming

⑥ Edge sealing

⑦ Filling

⑧ Sealing jaws

⑨ Cutting

⑩ Bag discharging

| Models | JW-E3220 | JW-E4230 | JW-E5235 | JW-E6240 | JW-E7245 | JW-E8350 | JW-H3220 | JW-H4230 | JW-H5235 | JW-H6240 | JW-H7245 | JW-H8350 |

| Applicable film width | 140-320mm | 160-420mm | 180-520mm | 180-620mm | 180-720mm | 180-830mm | 140~320mm | 160~420mm | 180~520mm | 180~620mm | 200~720mm | 180~830mm |

| Bag length range | 60-200mm | 60-300mm | 60-350mm | 80-400mm | 90-450mm | 90-500mm | 60-200mm | 60-300mm | 60-350mm | 80-400mm | 90-450mm | 60-500mm |

| Bag width range | 60-150mm | 70-200mm | 80-250mm | 80-300mm | 70-350mm | 60-400mm | 60-150mm | 70-200mm | 80-250mm | 80-300mm | 70-350mm | 80-400mm |

| Bagging speed | 15-70bags/min | 15-60bags/min | 15-60bags/min | 15-60bags/min | 0-70bags/min | 5-50bags/min | 15~100bags/min | 15~100bags/min | 15~90bags/min | 15~85bags/min | 0~70bags/min | 5~65bags/min |

| Power supply | 2.5KW/220/50/60HZ | 3.4KW/220V/50/60HZ | 3.4KW/220V/50/60HZ | 3.6KW/220V/50/60HZ | 5.5KW/220V/50/60HZ | 5KW/220V/50/60HZ | 2.9KW/220/50/60HZ | 4.5KW/220V/50/60HZ | 4.5KW/220V/50/60HZ | 5.1KW/220V/50/60HZ | 5.5KW/220V/50/60HZ | 6.5KW/220V/50/60HZ |

| Operation pressure | 0.6-0.8Mbra | 0.6-0.8Mbra | 0.6-0.8Mbra | 0.6-0.8MPa | 0.6-0.8MPa | 0.6-0.8MPa | 0.6~0.8Mbra | 0.6~0.8Mbra | 0.6~0.8Mbra | 0.6~0.8MPa | 0.6~0.8MPa | 0.6~0.8MPa |

| Gas consumption speed | 0.5m³/min | 0.6m³/min | 0.7m³/min | 0.8m³/min | 0.4m³/min | 1.2m³/min | 0.15m³/min | 0.2m³/min | 0.2m³/min | 0.2m³/min | 0.4m³/min | 0.4m³/min |

| Machine dimension (L×W×H) | 1158×930×1213mm | 1465×1040×1470mm | 1540×1160×1600mm | 1640×1226×1709mm | 1748×1344×1955mm | 1848×1544×2155mm | 1158×930×1213mm | 1400×1100×1560mm | 1514×1154×1590mm | 1640×1226×1709mm | 1748×1344×1955mm | 1848×1544×2155mm |

| Machine weight | 350Kg | 400Kg | 450Kg | 550Kg | 680Kg | 800Kg | 350Kg | 450Kg | 500Kg | 550Kg | 680Kg | 850Kg |

- Gusset device

- Gas flushing device (Nitrogen filling)

- Chain-bag capability

- Vibration device

- Round or Euro hole punch

- Custom sealing method

- Air flushing system

- Tear notch

- PE film sealing method

- Bag support device

- Static eliminator

- Vacuum device

- Horizontal-seal cooling system

- Automatic film alignment device

- Feeding device

- PLC RFID option for better security

- Multihead weigher

- Linear weigher

- Cup filler

- Auger filler

- Liquid pump