Pharmaceutical Wastewater Disinfection System

Request a Quote

Description

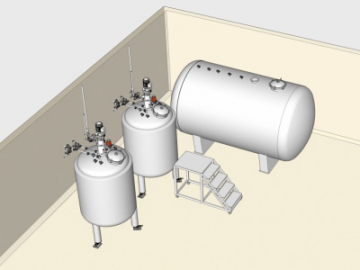

During the pharmaceutical process, there will be a lot of waste ware. The wastewater disinfection system produced by NJR is specially designed to eliminate the bacterial and virus in the wastewater to avoid contamination.

The system is mainly used in pharmaceutical industry which can harvest, ultra-filter, purify and inactivate with volume ranging from 50L -5000L.

Components- One storage tank

- At least two disinfection tanks

- Operation platform

- Pipes, valves and pumps

- Control system

- Tank body material

In order to achieve the GMP and FDA standards, 316L and 304 stainless steel are adopted as the raw materials. Also, nonferrous metals like titanium and other high alloy materials are also available depending on the products of clients. - Surface treatment

The interior surfaces of disinfection tank and storage tank are electropolishing finish with Ra≤0.4μm while the outer surface is mirror finish or matt finish. - Control system

In the disinfection system, all pumps and pneumatic stop valves is controlled automatically by PLC system so that it greatly reduces the labor cost and increase the production efficiency. - Piping design

L-shaped conversion pipe and quiet steam/water mixing valve are equipped inside the disinfection tanks to prevent water scale attached to the interior surface of tank and make it more convenient to clean. - Safety valve

A safety valve is fixed on the piping between the storage tank and disinfection tank so that the pressure inside tanks will stay in the calibration range when the disinfection tank is working. - Magnetic stirrer

At the bottom of tank, there is a magnetic stirrer to mix at low liquid level to make sure the uniformity of materials in the tank. This mixer can be suspending when it’s working or closing down so that the bearing will not distort or slip due to the heat caused by friction. - Tail gas filter

The exhaust pipe between the storage and disinfection tank is connected to a tail gas filter to prevent the waste gas does harm to environment. - Ventilation with heating function

Ventilation with heating function, which meets the GMP standard, is equipped to prevent the retention of condensate and the growth of microorganism.

- GMP

- TSG-2016 Supervision Regulation on Safety Technology for Stationary Pressure Vessel

- ISO2037

- FDA

- GB150.1~150.4-2011 Pressure Vessel

Related products

Send Message

Most Recent

More

Other Products

Videos