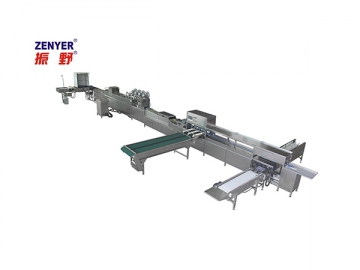

Processing Equipment for Evacuated Blood Collection Tubes (Modular Type)

Modular processing equipment for evacuated blood collection tubes combines several independent functional modules. Each module is individually controlled by a PLC, and gel filling is able to be achieved online. Only 3 operators are required for an output of 12000-15000 pcs/h.

Tube loading - dosing - inspecting - drying - inspection - capping - inspection - stoppering - vacuumizing- inspection - nest filling - subsequent wrapping

Tube loading

Automatic loading: two bulk loaders can be loaded to hold 20 tubes. Detection of tube clogging and reverse tube is available.

Atomizing dosing

An FMI precision ceramic metering pump, precision ceramic injection pump and high atomizing nozzle are used, ensuring an accurate filling, excellent stability, and easy operation. The filling amount can be set directly via touch screen.

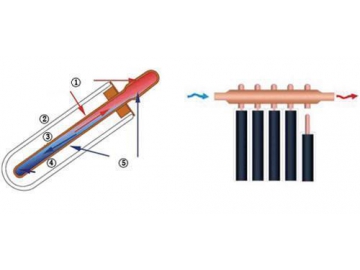

Drying

Four groups of drying systems feature a PTC heating mode, offering an outstanding drying effect, high production efficiency and no contamination. A positioning device is equipped between the heating rod and tubes to prevent the heating rod from damaging tubes. The drying system can be switched on or off according to production requirements.

Capping

A buffer zone for the cap and stopper is set, offering a high cap feeding efficiency. The unique cap picking and distance adjustment device allows for a smoother and more stable production process.

Vacuumizing

The high efficiency vacuum pump, high precision digital detector switch, Panasonic high precision proportional control and unique stoppering device allows for a rapid vacuumizing. The vacuum degree can be set directly via touch screen or automatically by system through choosing your local atmospheric pressure.

Nest/Tray filling

The equipment of a tube presence detection system ensures the right number of products and production process safety.

| Applicable tube size | Diameter: 13mm, height: 75mm or 100mm, Diameter: 16mm, height: 100mm |

| Capacity | 12,000 ~ 15,000 pcs/h |

| Filling accuracy | Anti-coagulant: ≤5%; Procoagulant: ≤6%; Large dose: ≤5% |

| Drying mode | PTC |

| Compressed air consumption | 0.6 ~ 0.8Mpa, 800 L/ min. |

| Power | 19KW |

| Overall size (L*W*H) | 7825*1200*2000mm |

| Power | 2tons |