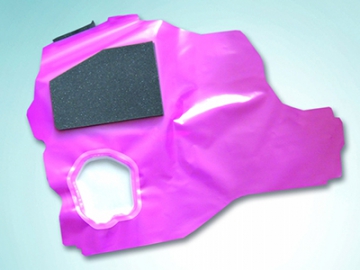

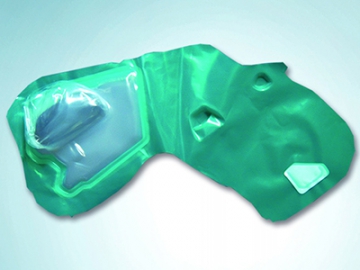

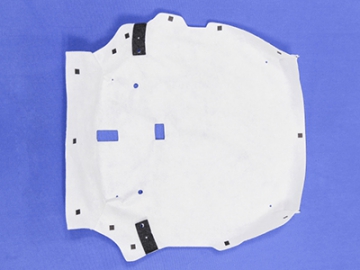

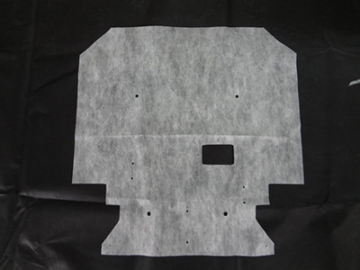

Automotive Door Water Shield Behind Trim Panel

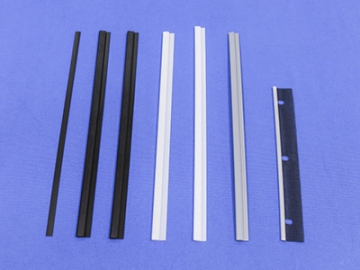

The automotive door moisture shield is located behind the trim panel on an automotive door. It is designed to prevent moisture from leaking into the circuit device inside the door, and thus, protect the automotive electrical components. The edge of the water shield is attached using a butyl sealant, which also protects against dust, oil and dirt.

PE film, IXPE foam. Other materials can be customized as needed

Thickness 0.03 ~0.5mm. Weight, shape and size specification can be customized.

The product is shaped using a vacuum forming machine, which is used after film blowing, and then attached using a high frequency welding machine.

- Dongfeng Nissan: Infiniti, Teana, X-Trailx-Trail, Sunny, Venucia

- Honda: CRV

- Toyota: RAV4, Highlander, Reiz, Crown, Prius, Prado, Previa, Land Cruiser

- Luxgen: L7, 5, R3, U6, U5

- Geely: Imperial

- Japanese Daihatsu: Pico, Materia, Copen,Sirion, Xenia

- Hawtai: SantaFe, Road, Bolgheri

Note: We have ready-made molds of the above types, which can be manufactured and processed quickly. If customers can’t find the type they need, simply contact us, and we will customize to meet your needs.

| Item | Technical standard | Testing methods | Testing standard | |

| Appearance | It is homogeneous, black, glossy and sticky solid | visual inspection | ―― | |

| Density | 1.40±0.10 g/cm3 | 23±2℃ | JC/T 942-2004 | |

| Temperature resistance | No flowing or breaking phenomenon | 150℃ | ASTM C792-93 | |

| Flexibility at low temperature | There is no crack on surface | -40℃,72h | ASTM C734-01 | |

| Elongation percentage | ≥400% | 23±2℃; 100mm/min | ASTM C736-00 | |

| Primary Adhesive property | 20 #steel ball(or more) | 23±2℃,Primary Adhesive Tester | GB/T 4852-2002 | |

| peel strength | ≥10 N/cm | 23±2℃; 100mm/min | ASTM D3330-02 | |

| shear strength | ≥20 N/cm | 23±2℃; 250 mm/min | GB/T 12952-91 | |

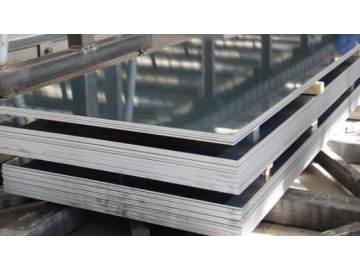

| Corrosion rate | Galvanized sheet and aluminum sheet | No scar or corrosion phenomenon | Soak 3/4 of it in distilled water at 38 ℃ for 168h | ASTM D925 |

| Copper sheet | No discoloration, etching, or corrosion | 70±2℃*168h | ||

| Odor | 2.8 grade | Sample:(200±20)cm2 | SMC 30156-2007 | |

| Shelf Life | 12 months | 5~35℃,Put it in a cool, dry room | ―― | |