Tooling Design and Manufacturing (Dies and Tools for Steel Wheel Manufacturing)

LittleDuck Precision Machinery Company is not only a major manufacturer of steel wheel manufacturing lines, but they also supply professional solutions for wheel rim die processing. We are ISO 9001 and ISO/TS 16949 certified, and own top of the line gantry machining centers, testing centers and debugging centers We provide solutions for designing, machining, and manufacturing wheel production lines, steel wheel tooling, and stamping tools.

We work with wheel, automobile and auto stamping companies, and they have consistently come to us for their needs. No matter what tools you need, whether it be for spoke manufacturing, tooling for wheel rim manufacturing, or stamping tools, we aim to meet your requirements.

As a prominent Chinese supplier of tools and dies for steel wheel manufacturing, LittleDuck owns a provincial enterprise technology center and post-doctoral research center, as well as a tool and technological equipment research center with more than 20 senior tooling R&D engineers and over 50 skilled and experienced engineering and technological employees.

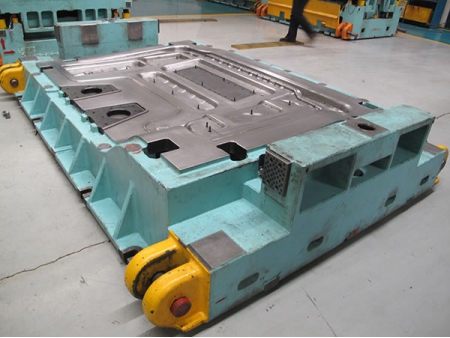

The tooling research institution specializes in the design and development of dies, gauges, fixtures, and welding stations for different types of steel wheel spokes and rims, as well as the design and development of stamping dies.

- Tooling Research Institution

- Technological Equipment Institution

LittleDuck has an excellent capacity in manufacturingwheel production tooling. We currently employ more than 50 professional technicians, and are well-versed in both domestic and international die material standards, such as the Chinese GB, American AISI, German SIN, Japanese JIS and others. In addition, we have a qualified purchasing system that is ISO 9001 certified, which ensure that the raw materials can meet design and manufacturing requirements.

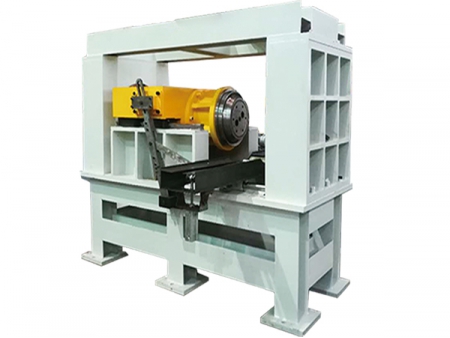

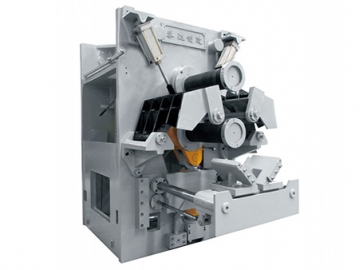

We have a diverse range of advanced production equipment for wheel spoke tooling wheel rim tooling and stamping tool manufacturing, including a large scale gantry machining center, horizontal machining center, vacuum quenching furnace, 1600T stamping line and other equipment.

- Large Scale Gantry Machining Center

Range of axis X, Y,Z: 5200×2600×920mm

Spindle speed: G6000rpm - Horizontal Machining Center

Machining range:2000×1450×1600mm

W axis range:650mm

Here at LittleDuck, we offer customers high quality wheel spoke and rim production tools, as well as stamping molds. We have established an excellent quality control system, which strictly enforces ISO9001 and ISO16949 standards throughout the whole process, from design to material supply, and all the way to the production and product test.

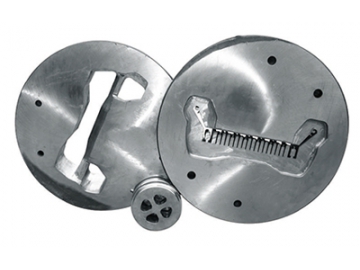

Our dies that are capable of completing valve hole punching on wheel spokes at one stoke, are rated as high precision dies by the China Die and Mold Industry Association (CDMIA). Our stamping tools and products have also been widely recognized among customers that are well known, including the China National Heavy Duty Truck Group Co., Ltd.

Main Processing Equipment- Award of High Precision Die

- Excellent Supplier

The following pages are a sample show of tooling for wheel spokes, discs, and wheel rim manufacturing, as well as our stamping tools. Check out each specific dies and tool we offer, in order to find the right one for your production of steel wheels.

Related Names

Flaring Tool | Expanding Tool | Roll Forming Tool | Tooling for Wheel Disc Making