D-Star Corrugated Board Converting Machine

(D-Star Full Vacuum Heat Transfer Flexo Printer Slotter Die Cutter)

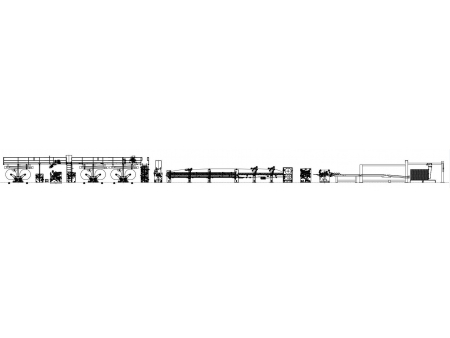

D-Star corrugated board converting machine is composed of 5 parts, which is the sheet feeder, the corrugated box printer, the UV coater & dryer, the die cutter and the central control panel.

D-Star corrugated board converting machine is mainly used for high-definition and high-speed printing, slotting and die cutting on various cardboard. The carton molding is completed in one step to meet the requirements of the majority of carton factory customers.

The sheet feeder adopts the servo drive and the feed rollers rotate to transfer the cardboard to the flexo printer for printing. After the cardboard reaches the flexo printer, the scraper system distributes the ink on the rubber roller evenly. After that, the rubber roller transfers the ink to the printing plate on the printing roller and the cardboard is transferred stably by vacuum adsorption, then the pattern is accurately printed on the cardboard. Afterwards, the cardboard is transfered to the slotter for slotting or the die cutter for die cutting to meet the customers's requirements in the shape of the carton.

- The central dust removal system adopts double dust vacuum transfer suction system, which makes the printed pattern more beautiful.

- The vacuum transmission box uses the method of partition feeding. Meanwhile, the bottom print shafts and the bellows wheels are all transmitted by ceramic wheels. This way can help lower loss and protect the cardboard from damage and the deliver process is more stable.

- The ink printing pressure are adjusted by using European special high-rate piston type to avoid mackle problems, which can accurate to 0.015mm.

- The corrugated box making machine has the function of one-button adjusting machine and spliting reset to zero, which can help remember 999 orders and the remembered oders can be ipmotred to ERP system to save the time of adjusting machine.

- The corrugated box making machine can automatically wash ink with fast speed in a cycle(3 minutes) and it has ink lacking alarming device with the technology of ink lacking alarming, which can prevent damage to the machine due to the lack of ink while high speed running.

- The corrugated box making machine has independent console and LED display, which is convenient for mechanical inspection and maintenance.

- The corrugated box making machine adopts closed double scraper and vacuum transmission system, the dryer adopts infrared, UV and quick drying oven (1350mm 1860mm 2350mm), which enhances the mechanical innovation and practicality.

| Model | JF0920 | JF0924 | JF1220 | JF1224 | JF1228 | JF1628 | JF1632 | JF1636 |

| Max speed (p/min) | 250 | 250 | 280 | 250 | 220 | 180 | 160 | 150 |

| Max feeding size (mm) | 900*2100 | 900*2500 | 1200*2100 | 1200*2500 | 1200*2900 | 1600*2900 | 1600*3300 | 1600*3700 |

| Min feeding size (mm) | 280*600 | 280*600 | 370*700 | 370*700 | 370*700 | 450*900 | 450*900 | 450*900 |

| Skip feeding size (mm) | 1200*2050 | 1200*2500 | 1600*2100 | 1600*2500 | 1600*2900 | 2000*2900 | 2000*3300 | 2000*3700 |

| Max print size (mm) | 850*2000 | 880*2000 | 1150*2000 | 1150*2400 | 1150*2800 | 1550*2800 | 1550*3100 | 1550*3500 |

| Min slotting gap | 230*70*230*70 | 230*70*230*70 | 230*70*230*70 | 240*70*240*70 | 240*70*240*70 | 280*70*280*70 | 280*70*280*70 | 280*70*280*70 |

| Printing plate thickness (mm) | 7.2 | |||||||

| Board thickness | 1.5-12 | |||||||

Jiufeng company offers corrugated board converting machine, we provide complete corrugated cardboard box machine line, including corrugated cardboard printer, cardboard slotter cutter, cardboard folder and gluer. The corrugated cardboard machines we made with plenty of experience since 1996, we are sure to offer customers high quality corrugated carton equipment and corrugated cardboard solutions for customers.