Co-Rotating Twin Screw Extruder

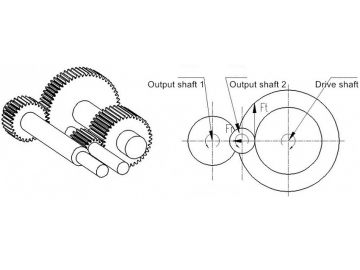

Parallel twin screws produced here at Omega are designed to meet performance and configuration needs of a variety of customers, both at home and abroad. The screw shaft is made of special materials, ensuring a speed of 900rpm or more, under specific high output requirements, a rate that is comparable to other leading screw extrusion equipment manufacturers. Users can choose to have their twin screw extruder equipped with not only the traditional 3 axis drive mode for the transmission box, but a double sided gear symmetrical drive mode. In order to ensure both the reliability and long service life of the gear box, we use SKF bearings made in Sweden, and INA bearings made in Germany for all of our gear boxes.

Our co-rotating twin screw extruder products are shown here. Users can choose from them, or contact us about customization information.All Omega brand twin extruders are equipped with standard high -chromium iron Ω101A oval liners that are comparable to liners from other leading companies. To satisfy needs for high glass fiber filling conditions, users can choose to have their equipment equipped with a high vanadium cast iron Ω102A oval liner- one of our most recently developed products, and features a better service life than the Ω101A. We can also provide users with nickel-based high-chromium alloy Ω301A oval liners for requirements where there is a higher risk of corrosion.

The thread curve of conveying element and the meshing surface of the kneading disk are designed according to equal gap meshing to ensure that both screws always maintain the same minimum meshing clearance during high speed co-rotation. For example, the unilateral clearance between the screw element and the inner wall of the barrel on the SHJ-H-27/48 model is 0.15mm, which is equivalent to the kneading gap on other leading twin screw extruders. Our company's screws meshing gap is smaller than that of our competitors, and features a better material mixing effect, a higher granulation product density, and better physical material properties.

We specially developed the HPCS-2000 control software for the parallel twin screw extruder’s control system, making it easier for users to monitor the formulation, metering, feeding to forming and other extrusion steps. It is easy, and allows for remote operation, and to ensure the stability and reliability of the extruder, our main DC motor uses a speed control from Eurotherm and Siemens, and the main AC motor’s variable speed frequency regulation is done using a Mitsubishi or Fuji AC frequency converter controlled by a Siemens PLC.

Temperature control is carried out using an RKC temperature control instrument from Japan, thanks to its two-way PID setting, artificial intelligence adjustment, high precision and other features, ensuring the overall accuracy. In addition, our control system also provides protection functions such as current overload protection, charging motor and main motor interlock, oil pump motor and main motor interlock, head pressure alarm, barrel temperature alarm, torque limit interlock, and more to ensure safe, long term operation.