AS-P11 Semi-Automatic Labeler (Top Labeling)

Request a Quote

The semi-automatic labeler is an air suction type labeling machine designed for applying labels to flat surfaces of different products, including flat bottles, packing boxes, and plastic caps. By changing the smoothing device, this machine also applies labels to uneven concave or curved surfaces.

The ribbon printer and industrial inkjet printer are optional. They print production dates and batch numbers on the label to achieve a combination of labeling and printing in one process.

Applications

- Applicable labels: self-adhesive label, self-adhesive film, electronic supervision code, bar code, etc.

- Applicable products: products requiring a label on a flat, arc, round, concave, or convex surface.

- Applicable industries: food, toys, daily chemicals, electronics, pharmaceutical

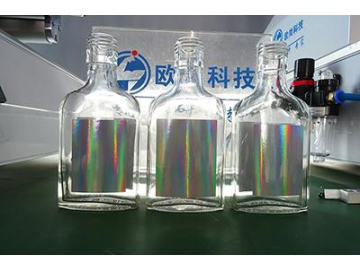

Samples

Specification

| Model | AS-P11 |

| Label stop accuracy | ±0.5 mm |

| Production speed | 15-35 pcs/min |

| Product length | 20mm~300mm |

| Product width | 20mm~150mm |

| Product height | 0.2mm~200mm |

| Label length | 15mm~200mm |

| Label roll inside diameter | Φ76mm |

| Label roll outside diameter | Φ280mm |

| Dimensions (length x width x height) | 850mm x 410mm x720mm |

| Weight | 48Kg |

Details of Top Labeler

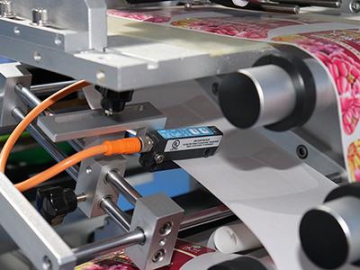

Photoelectric sensor

Photoelectric sensor

The labeling machine is equipped with a photoelectric sensor made by Sick and features an exceptionally high precision and reliability. Touch screen:

Touch screen:

The touch screen is PLC controlled with an easy to use human to machine interface. With just a tap of the screen, users can set different functions and parameters according to their needs. Coding machine:

Coding machine:

The coding machine prints information such as a batch number on the label during the labeling process. Easy to adjust:

Easy to adjust:

Its stroke is adjustable, making it easy to label products with different heights.

Related products

Send Message

Most Recent

More

Other Products

Videos