AS-P16 Semi-automatic labeler (Wrap Around Labeling/ For Round and Multi-sides Bottles)

Request a Quote

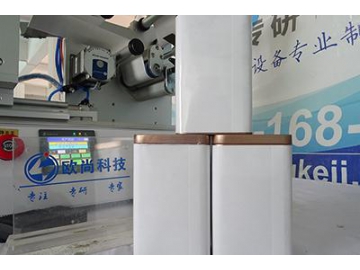

The semi-automatic labeler is equipped with a rotating motor and roller for labeling different products and shapes, including flat surfaces, and round or square bottles. As an example, it applies labels to three sides of a honey bottle, or all 4 sides of a tea caddy. By changing the smoothing device, it applies labels to uneven surfaces such as a concave or curved surface. With the use of different jigs, the semi-automatic labeler will also apply labels to irregularly shaped products.

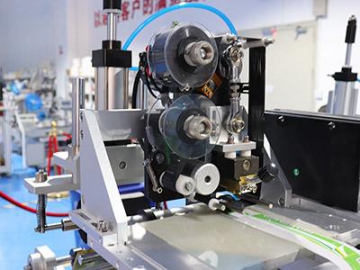

The ribbon printer and industrial inkjet printer are optional. They are used for printing the production date and bath number on labels, combining printing and labeling processes.

Applications

- Applicable labels: self-adhesive label, self-adhesive film, electronic supervision codes, bar codes

- Applicable products: products requiring a label on a flat, cambered, round, concave or convex surface

- Applicable industries: cosmetics, food, toys, daily chemicals, electronics, pharmaceutical, and more.

Samples

Specification

| Model | AS-P15 |

| Label stop accuracy | ±1 mm |

| Production speed | 40-200 pcs/min |

| Product length | 15mm~100mm |

| Product width | 30mm~120mm |

| Product height | 0.2mm~120mm |

| Label length | 5mm~130mm |

| Label roll inside diameter | Φ76mm |

| Label roll outside diameter | Φ280mm |

| Dimensions (length x width x height) | 800mm x 950mm x600mm |

| Weight | 50Kg |

| Air pressure | 0.4-0.6Mpa |

Details of Top Labeler

Photoelectric sensor

Photoelectric sensor

The labeling machine is equipped with a photoelectric sensor provided by Sick and features an exceptionally high precision and reliability. Touch screen:

Touch screen:

The touch screen is PLC controlled, with an easy to use human to machine interface. With just a tap of the touch screen, users can carry out an array of functions and determine a variety of product parameters to meet specific requirements. Coding machine:

Coding machine:

The coding machine will print vital information on the label during the labeling process, such as batch numbers. Rotating motor:

Rotating motor:

It is used to rotate different products, including round bottles, square bottles, flat bottles and faceted bottles for label applications.

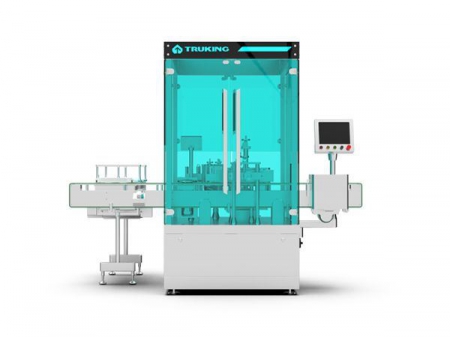

Related products

Send Message

Most Recent

More

Other Products

Videos