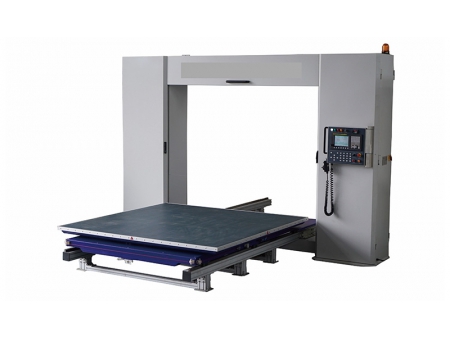

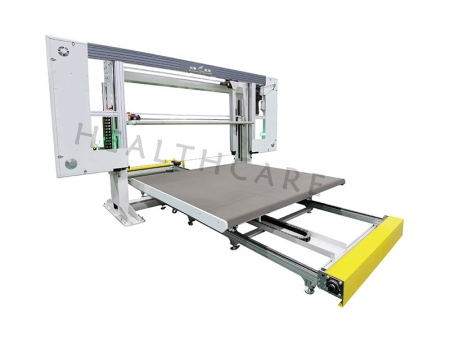

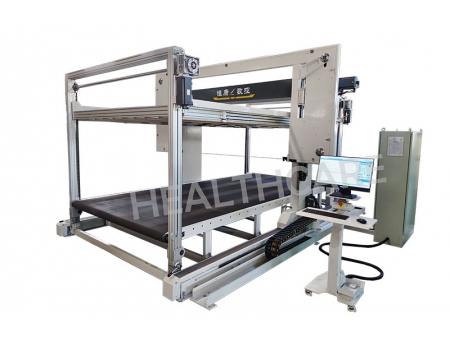

LH5 CNC Horizontal Wire Foam Cutting Machine

Application

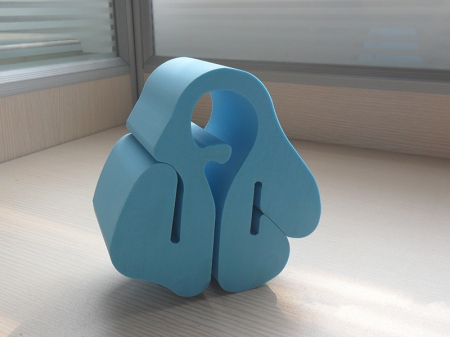

LH5 CNC Horizontal Wire Foam Cutting Machine could be utilized to cut thermal insulation material, bed mattress or furniture cushions, car upholstery, packaging materials and other industrial materials.

Materials to be cut

EVA, rigid foam (PU, PIR, EPS, Phenolic resin and etc.), flexible foam (traditional sponge, slow recovery foam and etc.)

Shapes

LH5 CNC Horizontal Wire Foam Cutting Machine could cut foam into block, wavy, curved regular and irregular shapes.

| Standards | |

| Length of the foam block | 2200mm |

| Height of the foam block | 1250mm |

| Width of the foam block | 2200mm |

| Work table | 90 degrees rotation is allowable |

| AC power | 380V 3 phase 4 wire |

| Total power | 6KW |

| Cutting precision | ±0.1mm |

| Cutting tool | Pressure: 6 bar - Continuous blade - Wire cutting speed: 6 ~ 50 m / s - Diameter: 1.3mm |

| Operating option | Automatic Rotary worktable - Automatic programming software - FANUC control system - Manual pulse generator(Optional) |

| Max. cutting speed | Different cutting materials will be cut at different speed. And the max. speed is 15 meters/minute. |

Features:

LH5 use more standard and more stable FANUC control system,It's performance have greatly promoted,such as:cutting speed promoted 50%,cutting precision promoted one times.

LH5 CNC Horizontal Wire Foam Cutting Machine utilizes FANUC control system, which enjoys a more stable operation and an improved performance, like 50% higher cutting speed, and bettered cutting accuracy, which is one time higher than the precious one.

1. 50% higher cutting speed

2. Largely improved cutting accuracy

3. Multiple operation systems

a. Motion control system

b. FANUC control system

4. Manual pulse generator’s installation makes the cutting machine easy operated.

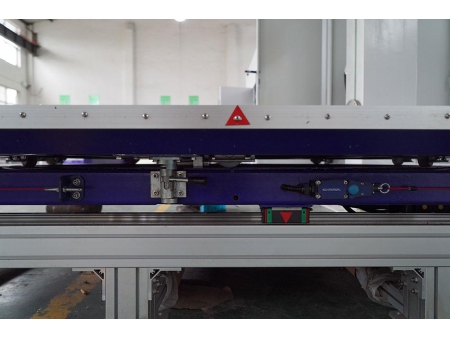

5. Optimized working condition: Ball screw and slide are all covered by dust guard. Meanwhile, in order to ensure timely dust removal, dust collector is also utilized.

6. High safety factor: Emergency stop button’s installation makes our cutting machine safer and well prevents operation personnel’s hurting. In addition, we also installed orange protective guard, which is eye-catching.