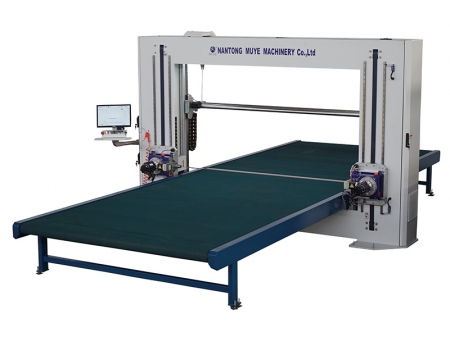

Fastwire CNC Contour Cutter, CNCHK-1

CNC Foam Cutting Machine for EVA and Rigid Foams

CNCHK-1 is the first generation of CNC foam cutting machine in our company, and is also the first one in the Chinese foam contour cutting industry. This foam processing machine features simple operation and high cutting speed, which is widely used in the production of automobile parts, upholstered furniture, and mattresses, as well as in the packaging and insulation industries. With the development of CNC contour cutting technology, CNC contour cutter with blade becomes an outstanding alternative to wire CNC foam cutting machine. Although foam dust will be generated during the contour cutting, wire foam cutters are still the great contour cutting option in the foam production, because it's capable of cutting various foam materials including rigid PU foam, EVA, PE and PEE.

CNCHK-1 is the first generation of CNC foam cutting machine in our company, and is also the first one in the Chinese foam contour cutting industry. This foam processing machine features simple operation and high cutting speed, which is widely used in the production of automobile parts, upholstered furniture, and mattresses, as well as in the packaging and insulation industries. With the development of CNC contour cutting technology, CNC contour cutter with blade becomes an outstanding alternative to wire CNC foam cutting machine. Although foam dust will be generated during the contour cutting, wire foam cutters are still the great contour cutting option in the foam production, because it's capable of cutting various foam materials including rigid PU foam, EVA, PE and PEE.

EVA insole

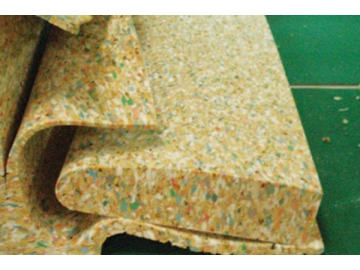

EVA insole  Rebond foam

Rebond foam Insulation material

Insulation material

- Insulation materials

- Sporting goods

- Packaging

- Rigid foam

- Rockwool

- Rebond foam

- EVA

- PE/EPE

| Machine weight | 2.4t | CNC Type | Industrial computer |

| Power supply | 8kW, 380V, 50Hz | Control panel | LCD display |

| Machine dimensions | 5000x3000x2800mm | Control module | Motion control card |

| Max. block size | 2500x2100x1200mm | Operating system | Windows 2000 or upgraded version |

| Cutting wire size | 10830x1.5mm | Programmable axis | X, Y, ψ |

| Speed of wheel | 2800r/min | Stepper motor torque | 20Nm |

| Cutting speed | 0-6.3m/min | Mini. cutting radius | 10mm |

| Tolerance | ±0.5mm | Self-diagnostic function | Yes |

| Min. cutting thickness | 5mm | Alarm for wire breakage | Yes |

- The abrasive wire can cut through a variety of material types

- Simple operation with state-of-the art control technology

- Maximized material efficiency due to ZWCAD function in combination with Nesting function for an automated mode of operation.

- High machine availability due to high quality parts with a long service life and easy access to spare parts.

- Dust extraction unit

- Wire breakage alarm

- Fault alarm

- Vertical wire knife

- Vacuum table

- Roll compression unit (press roller)