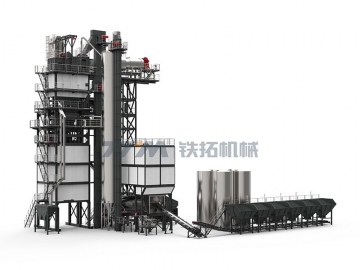

Integrated Hot Mix Asphalt Recycling Plant, TS Series

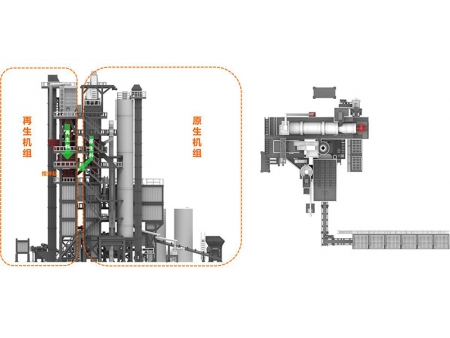

TS series asphalt plant is our independently developed integrated hot mix asphalt recycling system to recycle reclaimed asphalt pavement (RAP) by mixing it together with virgin aggregates thereby enabling the reclaimed asphalt from old roads to be reused in an environmentally friendly way. The RAP recycling plant can not only solve environmental problems, but also help road construction companies lower their cost.

Since the mixer is installed beneath the RAP weighing system, which means the RAP material is weighed before being mixed with virgin materials, so that this asphalt plant can solve the material blocking issues that may occur in RAP materials feed chute or belt conveyor. The integrated structure design provides optimal configuration of dust collection system and mixer, greatly improving production efficiency.

| Model | <>TS3015 | ||||||

| Capacity of virgin aggregate (t/h) | 80 | 120 | 160 | 160 | 160 | 240 | 320 |

| Capacity of RAP material (t/h) | 48 | 80 | 80 | 120 | 120 | 160 | 160 |

| Recommended RAP ratio | 40% | 50% | 33% | 50% | 37.50% | 50% | 40% |

| Capacity of virgin aggregate with RAP (t/h) | 100-120 | 140-160 | 200-240 | 200-240 | 280-320 | 280-320 | 360-400 |

| Virgin Aggregate | |||||||

| Cold feed unit | The number of cold feed bins can be configured according to customer needs | ||||||

| Number of hopper | 4 | 4 | 5 | 5 | 6 | 6 | 6 |

| Volume of single hopper (m³) | 8 | 8 | 8 | 8 | 15 | 15 | 15 |

| Drum dryer model | GT 100 | GT 120 | GT 140 | GT 160 | GT 240 | GT 240 | GT 320 |

| Dryer drum diameter (m) | 1.75 | 1.95 | 2.25 | 2.25 | 2.5 | 2.5 | 2.7 |

| Dryer drum length (m) | 7 | 8 | 9 | 9 | 10 | 10 | 10 |

| Dryer burner | Optional: diesel, diesel heavy oil, coal powder, natural gas, oil gas (as per customer's request) | ||||||

| Burner power (MW) | 9.8 | 14.8 | 19.7 | 19.7 | 29.6 | 29.6 | 39.4 |

| Dust collection system | Cyclone baghouse | ||||||

| Filtering area of baghouse (m²) | 510 | 650 | 920 | 920 | 1200 | 1200 | 1500 |

| Number of hot bin | 4 | 5 | 6 | ||||

| Volume of hot bin (m³) | 12 | 25 | 28 | 50 | |||

| Mixer capacity (kg) | 1500 | 2000 | 3000 | 4000 | 5000 | ||

| Transmission of mixer | Double gearbox with gear synchronization | ||||||

| Finished asphalt storage | Under-storage/side-storage | ||||||

| Volume of under-storage bin (t) | 100 | 200/300 | 200/300/400 | ||||

| Volume of side-storage bin (t) | 100/200 | 200/300/400 | |||||

| RAP Material | |||||||

| Drum dryer model | RGT64 | RGT80 | RGT80 | RGT120 | RGT120 | RGT160 | RGT160 |

| Dryer drum diameter (m) | 1.8 | 2.25 | 2.5 | ||||

| Dryer drum length (m) | 8 | 8 | 10 | 12 | |||

| Dryer burner | Optional: diesel, diesel heavy oil, coal powder, natural gas, oil gas (as per customer's request) | ||||||

| Burner power (MW) | 5.9 | 9.8 | 14.8 | 19.7 | |||

| Combustion chamber (diameter×length) | Ø1.6×3.8 | Ø1.8×4.2 | Ø2×4.2 | ||||

| Storage of RAP (t) | 8 | 10 | |||||

| RAP mixer | Optional | ||||||

| Capacity of RAP mixer (kg) | 600 | 1000 | 1500 | 2000 | |||

| Emission handling | Secondary combustion in the dryer of virgin materials | ||||||

| RAP feeding to mixer | Feed chute or conveyor belt | ||||||

| Total power (kW) | 90 | 110 | 160 | 160 | 185 | 185 | 200 |