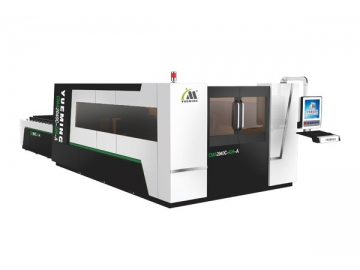

2000×4000mm Large Format Fiber Laser Cutter, CMA2040C-G-A Laser Cutting System

Applicable Materials

The CMA2040C-G-A is applicable for quick cutting metal materials, such as carbon steel, stainless steel, aluminum alloy, titanium alloy, galvanized sheet, aluminum coated zinc plate, brass, red copper and more.

| Model | CMA2040C-G-A |

| Laser power (W) | 700-2000 |

| Working area (mm) | 2000×4000 |

| Overall dimension (mm) | 6400×2700×2000 |

| Weight (kg) | 4800 |

| Position accuracy (mm) | ±0.03/1000 |

| Reposition accuracy (mm) | ±0.02/1000 |

| Maximum speed (m/min) | 60 |

| Maximum accelerated speed (G) | 0.8 |

| Power supply | Three phase 380V/50Hz/60Hz |

| Working environment | Temp: 0~ 45°C Humidity: ≤80% No condensate water, no dust or less dust. |

Laser Processing Examples:

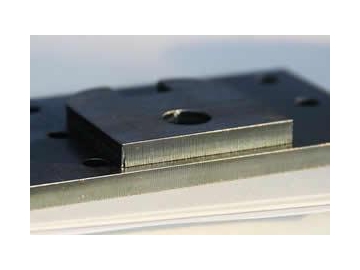

Laser cutting of 5mm carbon steel

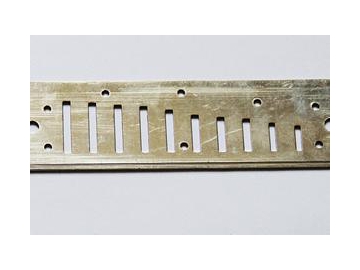

Laser cutting of 5mm carbon steel Laser cutting of aluminum alloy window

Laser cutting of aluminum alloy window Laser cutting of aluminum plate

Laser cutting of aluminum plate Laser cutting of carbon steel

Laser cutting of carbon steel Laser cutting of carbon steel

Laser cutting of carbon steel Laser cutting of central air conditioning

Laser cutting of central air conditioning Laser cutting of sheet metal parts

Laser cutting of sheet metal parts Laser cutting of titanium

Laser cutting of titanium

Product Feature

1.Equipped with a reinforced welded lathe bed and a finish milling processed double drive gantry. The non-metal laser cutting machine is annealed and processed by vibration aging technology to relieve stress and control the deformation deviation within ±0.02mm.

2.The crossbeam made through draw aluminum profiles and processed by finishing machining features light weight, high rigidity and good dynamic performance.

3.The cutting head features leapfrog function. Parabolic motion is adopted when cutting contours and leapfrog movement is available when switching cutting contours, which greatly improves cutting efficiency.

4.The crossbeam features system-controlled automatic concentrated lubrication without manual intervention, which ensures the motion precision and service life of the transmission parts.