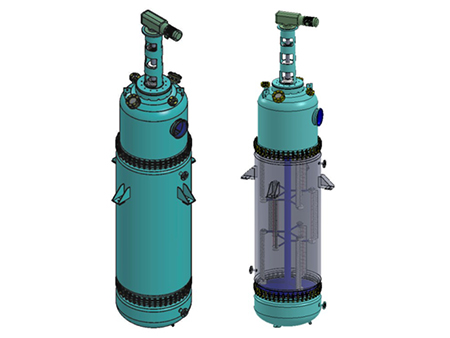

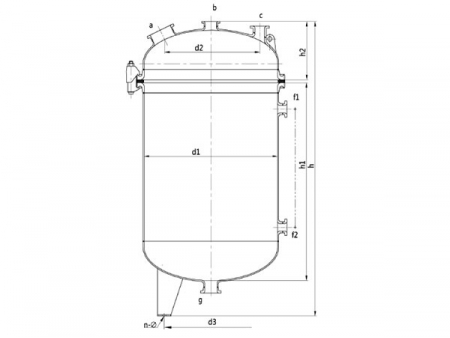

Glass-Lined Storage Tank, K Type

The K type glass lined storage tank features an open-type design. That means the cover and tank body are assembled using clamps and gasket, and they can be separated. This design ensures ease of maintenance and makes it convenient to replace parts. Due to special process, this type of glass lined receiver comes with relatively small volume. However, it offers exceptional corrosion resistance, sheer reliability, stable lining and long service life.

According to different capacities, our open type glass lined storage tank is divided into various models including K50L, K100L, K200L, K300L, K500L, K1000L, K1500L, K2000L, etc. In addition to standard glass lined steel stank, we are also able to make non-standard products to customers' needs.

| Inner Vessel | |

| Design Pressure ( MPa ) | ATM |

| Design Temperature ( ℃ ) | -19 ℃ /150℃ |

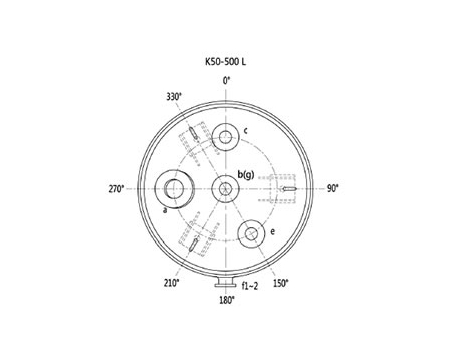

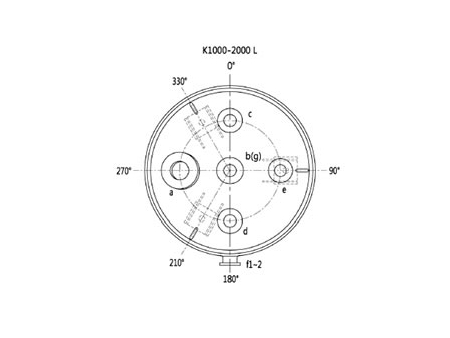

| Symbol | Usage |

| a | Handhole / Manhole |

| b | Medium Inlet |

| c, d, e | Spare |

| f1, f2 | Level Gauge Hole |

| g | Medium Outlet |

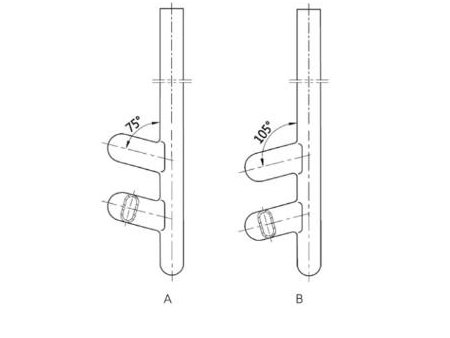

K50-K500L Nozzles Layout (Plan View)

K50-K500L Nozzles Layout (Plan View) K1000-K2000L Nozzles Layout (Plan View)

K1000-K2000L Nozzles Layout (Plan View)| Unite:mm | |||||||||

| Specifications | |||||||||

| Nominal Capacity (L) | 50 | 100 | 200 | 300 | 500 | 1000 | 1500 | 2000 | |

| Total Capacity (L) | 80 | 155 | 294 | 447 | 740 | 1480 | 2020 | 2800 | |

| Calculated Capacity(Notes 1) (L) | 61 | 121 | 237 | 362 | 620 | 1270 | 1670 | 2370 | |

| Reference Weight (kg) | 95 | 160 | 210 | 285 | 395 | 716 | 970 | 1266 | |

| Main Dimension | d1 | 400 | 500 | 600 | 700 | 800 | 1000 | 1200 | 1300 |

| d2 | 320 | 350 | 420 | 420 | 480 | 600 | 720 | 780 | |

| d3 | 280 | 350 | 420 | 490 | 560 | 700 | 700 | 910 | |

| h1 | 520 | 660 | 890 | 1000 | 1310 | 1695 | 1580 | 1895 | |

| h2 | 249 | 274 | 309 | 334 | 390 | 439 | 490 | 514 | |

| h | 1150 | 1095 | 1340 | 1750 | 1885 | 2310 | 2240 | 2670 | |

| n-Φ | 3-Φ15 | 3-Φ20 | 3-Φ20 | 3-Φ25 | 3-Φ25 | 3-Φ25 | 3-Φ25 | 3-Φ25 | |

| Nozzle DN | a | 80 | 100 | 125 | 125 | 150 | 150 | 200 | 300×400 |

| b | 65 | 65 | 65 | 80 | 80 | 80 | 100 | 100 | |

| c | 65 | 65 | 65 | 65 | 80 | 80 | 80 | 80 | |

| d | / | / | / | / | / | 80 | 80 | 80 | |

| e | 65 | 65 | 65 | 65 | 65 | 80 | 80 | 80 | |

| f1 | / | 65 | 65 | 65 | 65 | 65 | 65 | 65 | |

| f2 | / | 65 | 65 | 65 | 65 | 65 | 65 | 65 | |

| g | 65 | 65 | 65 | 80 | 80 | 80 | 100 | 100 | |

| Notes 1: Calculated Capacity: Volume under highneck flange | |||||||||

- No.100, Taishan Road, New Century Industrial Park, Guoli, Huantai District, Zibo City, Shandong Province

- 86-533-8409960

- 86-15053366638

- 15053366638

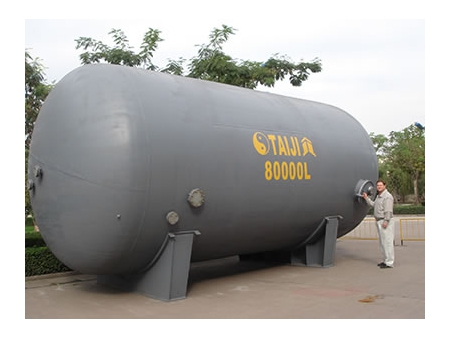

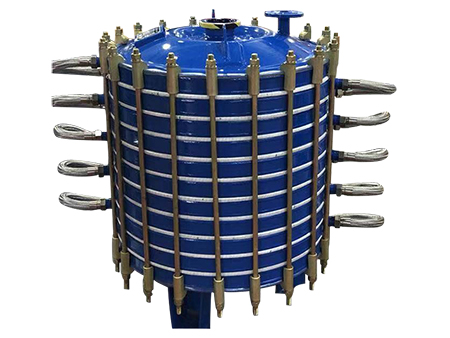

Taiji has decades of experience in the construction and delivery of glass-lined equipment for chemical, pharmaceutical, food processing industries, etc. We are certified for the fabrication of glass-lined products by ASME, PED and RTN. As an experienced glass-lined vessels manufacturer, we understand the selection, layout and manufacturing of glass lined process equipment and their spare parts is critical for the reliability of their production as well as essential for the secure process and storage of corrosive, poison and dangerous chemicals. Therefore, our glass lined steel equipment such as glass-lined reactor and storage tank, pressure vessel is the long-recognized standard in the chemical process industries. Taiji has the capability to adapt our services to your individual requirements.