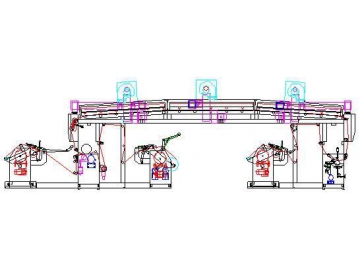

Automatic Dry Laminating Machine GSGF800A/1100A

Deguang’s automatic dry laminating machine is applicable to BOPP, PET, CPP, PVCD, aluminum plated film, aluminum foil, as well as the composite film and paper with the same properties. Its mechanical speed is130m/min.

Dry Laminating Machine Configuration- Main transmission unit: It uses an AC variable frequency vector control. The glue spreading rubber roller and hot drum are synchronized in terms of speed and use the swing arm to control the tightness and looseness of the film in the channel.

- Material feeding device: Group one and two feeding devices use a dual station inching reversing and use a double photoelectric edge-correcting device. Automatic tension control is achieved.

- Material receiving device: It uses a dual station inching reversing and automatic material collecting. A moment motor is involved in material receiving.

- Rubber spreader: The anilox rollers control the scrapping and inking amount through doctor blades. The rubber roller features a dual air cylinder to increase the pressure while the pressure is also freely adjustable. The laminating film can lift automatically while the dry laminating machine stops.

- Oven tunnel: The tunnel is divided into three sections, and the temperature in each is controlled independently through an intelligent temperature controller. In addition, these sections are also independently dried by the hot air drying system and hot air is recycled for reuse. The material-protecting roller and the hot drum rotate synchronously.

- Laminating hot drum and impression roller: The laminating hot drum is heated using heat conducting oil, which not only ensures heating uniformity but also saves electricity. The impression roller is controlled by a dual air cylinder.

| Model | GSGF-800A | GSGF-1100A |

| Laminating layers | 2 | 2 |

| Laminating width | 800mm | 1100mm |

| Diameter of material cylinder | 600mm | 600mm |

| Adjustable range of laminating linear speed | 50-120m/min | 50-120m/min |

| Max. adjustable temperature of drying oven | 80℃ | 80℃ |

| Max. adjustable temperature of hot drum | 70℃-90℃ | 70℃-90℃ |

| Tension ratio | ≤1/1000 | ≤1/1000 |

| Total power | 78kw | 92kw(with electric hot plate) |

| Weight | 8000kg | 9500kg |

| Overall dimensions (L×W×H) | 11500×2500×3150 mm | 11500×2800×3150 mm |

Deguang Machinery is a leading automatic dry laminating machine manufacturer inChina, and is an expert in manufacturing and marketing a comprehensive range of rotogravure printing machines, slitting machines, laminating machines, and more. As a result of their high quality and low prices, our products are very popular with customers in many countries, such as India, Iran, Egypt, Russia, Brazil, Vietnam, Malaysia, Pakistan, and more. If you buy these products from our company, we can also provide you with convenient transportation, especially sea and air transportation. We sincerely hope to cooperate with you!