630mm Spool Triple Twist Twinner for Twisted Pair

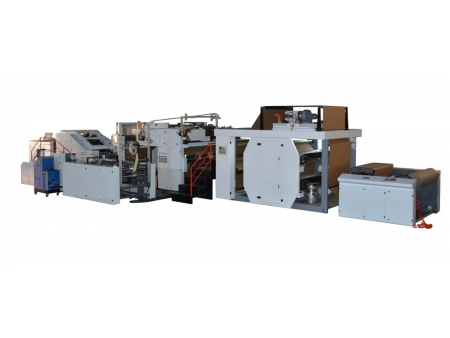

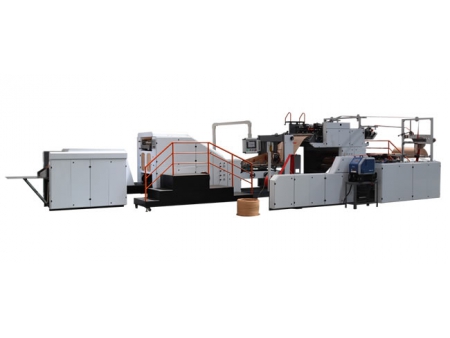

The twist twinner is applicable for twisting LAN cable (CAT5 cable, CAT5E cable, CAT6 cable, CAT7 cable), insulation core wire, telecommunication cable, etc. It has two layers of reel with diameter 630mm. This model of equipment is self-equipped with back-twisting function and thus additional back-twisting machine is not required.

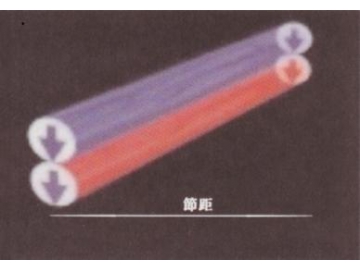

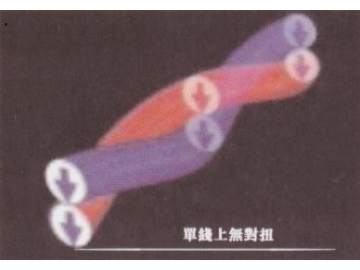

Effect after twisting

Effect after twisting CAT5 cable , CAT6 cable

CAT5 cable , CAT6 cable CAT5 cable , CAT6 cable

CAT5 cable , CAT6 cable CAT7 cable

CAT7 cable CAT7 cable

CAT7 cable

- Single wire diameter: max 1.5mm

- Rotation speed: max 2000rpm (6000TPM)

- Line speed: max 120m/min

- Back-twist rate: 0 – 100%

- Pitch range: 10 – 60mm

- Pitch tolerance: ±2%

- Pay-off reel size: 630mm

- Take-up reel size: 630mm

- Main power: 7.5KW

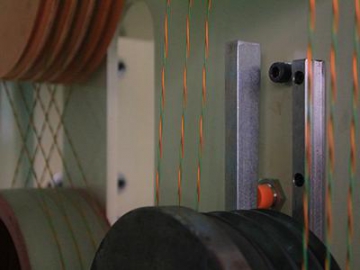

Two layer reel

Two layer reel Servo motor controls wire twisting

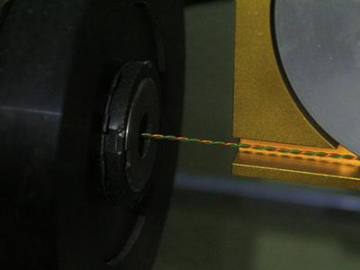

Servo motor controls wire twisting Twisting details

Twisting details Take-up details

Take-up details

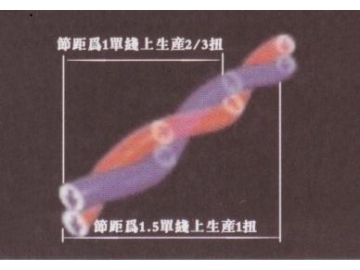

1. The back-twist rate can be set in the range 0-100% so that the property of the wire achieves requirements of type 5,6 and 7.

2. The twinner adopts triple twisting design with 1.5 times faster speed than general double twisting machine while it is at back-twisting rate of 33%.

Single line of the pay-off reel

Single line of the pay-off reel Product after pay-off

Product after pay-off Final triple twist

Final triple twist

3. Two layers of twisting reel, one time faster speed than single line twist twinner. This kind of structure design helps to reduce the floor area.

4. The tension of the take-up line is fully controlled by force. Constant tension control is maintained from the empty to the full reel.

5. Fast twisting speed. The maximum speed reaches 6000TPM/min. 50% faster speed than the traditional back-twister.

6. This cable twist twinner equipment self-integrated twist-back and twisting function to avoid self-twisting when two conductors are twisting. As compared to the traditional back-twitter + twister, it has compact design structure with half of the size of the traditional machine, effectively save up the space of the factory.

7. Low power consumption, total power of the equipment is 15kw, one third lower power compared to the traditional back-twister + twister, reduces the production cost greatly.

8. Easy operation and fast line speed.

9. Adopt PLC control system to automatically adjust the twisted wire pitch by the servo motor, replacement of taper gear is unnecessary, more accurate operation.