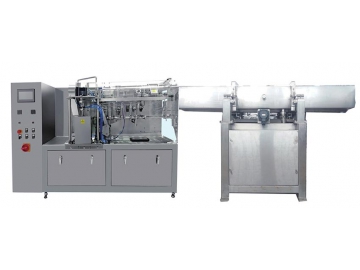

JDG-180D/240D, Pre-made bag Rotary System Pouch Packaging Machines

The JDG-180D/240D pre-made bag rotary system pouch packaging machines are the same as JDG-180/240 as far as packing bag types and packing bag sizes. However, this series produces 2 pouches/cycle, which is twice as fast as the JDG-180/240. If you need highly efficient packaging machines, we recommend the 180D/240D, as it is designed to package solids, liquor, powder, puffed foods, dairy products, coffee grounds, and pharmaceutical products.

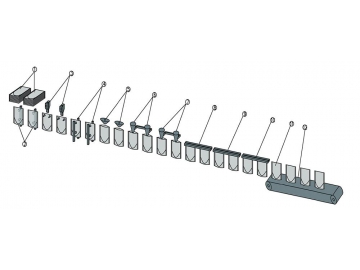

1. Double Premade Pouch Stack

2. Double Flip-Out Pouch-Picking

3. Double Zipper Opening

4. Double Pouch Opening

5. Double Air Flushing

6. Filling Ⅰ

7. Filling Ⅱ

8. Top Seal Ⅰ

9. Top Seal Ⅱ

10. Cold Seal

11. Finished Product

12. Product Outlet

| Type | Minimum Bag Size (mm) | Maximum Bag Size (mm) | Packing Capacity (ml) | Packing speed (ppm) | Power (kw) | Gas consumption (NL/min) | Weight (kg) | Equipment Size (mm) |

| JDG-180D | 80*110 | 90*230 | 200 | 100-120 | 3.5 | 0.45 | 900 | 1800*1300*1500 |

| JDG-240D | 100*240 | 120*320 | 300 | 100-120 | 3.5 | 0.5 | 1000 | 2000*1300*1500 |

· Independent Film Unwind Unit

· Better doypack forming

· Ensure good control of film tensile force

· More flexible and suitable for different pouch specifications

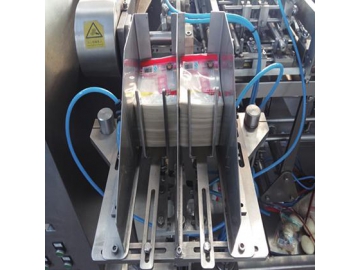

· Dual Filling Station

· Reduce filling time by half

· Improved filling accuracy

· Fill 2 products simultaneously

· 2 Top Seal Unit

· Ensure seal strength, no leakage

· Even seal with good appearance

· Higher adaptability of film material