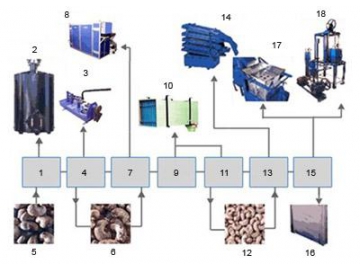

Auxiliary Equipment

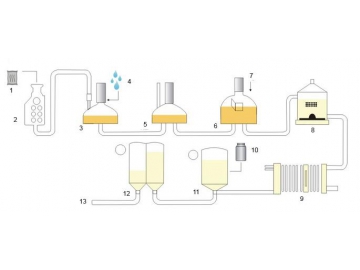

The auxiliary equipment system consists of the cooling unit, air compressor, and either the steam boiler or electric heating steam generator. Water treatment units are added by request. Our system can satisfy the requirements of water brewing, steam heating, and electric heating. It also provides the refrigerant and compressed air required for the brewing of beer with specifications such as 50L, 100L, 200L, 300L, 500L, 800L and 1000L.

The water quality of a beer brew is closely associated with the beer state. Firstly, the brewing water must meet drinking water standards and comply with the values of indexes such as pH and hardness. This set of equipment is entirely optional and should be equipped if needed.

The beer bar can be considered as a mini beer-making-machine. The primary heat source is generally supplied by either an electric steam generator or electric heating steam boiler. Direct heating via electricity is also an option.

The electric heating steam generator/boiler consists of the electric heating and steam generating system. We utilize equipment with evaporation capacities of 30, 50, 100, and 200Kg/h. These capacity settings are powered by 24, 36, 72 and 144Kw, respectively.

Beer fermentation occurs at a low temperature, typically between the range of 6 to 15℃. Storage temperature is best kept at 1 to 5℃. Refrigeration equipment is required for production.

Beer bars can be refrigerated with either air cooling or water cooling. The industrial water chilling unit is an excellent choice. This unit has a refrigeration capacity of 20 to 50Kw and utilizes a R22 or R407C refrigerant. Chilling water can be used as a refrigerant for wort cooling, ethylene glycol is preferred for the cooling and heat preservation of fermentation tanks and bright beer tanks.

Pressurized sterile air provides the oxygenation required for wort production. This is typically done after cooling and prior to fermentation, which requires the oil-less air compressor to supply a viable source of oxygen. In essence, the air compressor must have an air displacement of 100 to 300L/min and an installed power of 2.2 to 5.5Kw.

Jiadi is a specialized beer brewing equipment for beer bar manufacturer and supplier in China. We provide a variety of products, including tunnel spray sterilizer and cooler, orange juice concentrate processing line, vacuum evaporator, sachet packing machine, and more.

Related Names

Water Treating Equipment for Beer Brewing | Steam Generating Unit | Beer Brewing Cooler