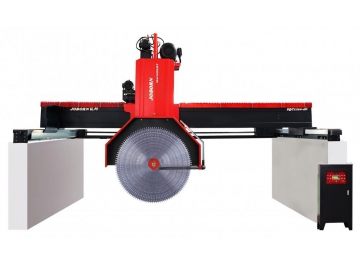

Block Cutting Bridge Saw, Marble and Granite Cutting Saw

- Materials suitable for cutting: huge granite and marble blocks.

- Size suitable for cutting: 3.8m x 0.95m

- Blade diameter range: 2.2m-2.8m

- Maximum cutting depth: 950 mm

Equipped with many circular blades with diameters of 2.8 m, the block cutting bridge saw, marble and granite cutting saw can cut huge blocks all at one time, which is very efficient. Adopting a microcomputer control system and an intuitive interface, the stone machinery is positioned by the infrared laser alignment device and adjusted by German Bosch frequency converter. The stone cutting machine is easy to use to achieve precise cutting. Designed by professional Italian industrial design team, with special paint and spray paint technology. A multi-layer antirust and anticorrosion treatment is applied, this kind of stone cutting machine has strong oxidation resistance.

Cutting effect| Appellation | Unit | SQC2200-4D | SQC2500-4D | SQC2800-4D |

| Max. disc diameter | mm | Φ2200 | Φ2500 | Φ2800 |

| Max. processing length | mm | 3800 | 3500 | 3200 |

| Max. processing width | mm | 2200 | 2200 | 2200 |

| Max. lifting stroke | mm | 1350 | 1350 | 1350 |

| Water consumption | m³/h | 15 | 15 | 15 |

| Power of main motor | kW | 37 | 45 | 55 |

| Total power | kW | 48 | 56 | 66 |

| Dimension (LxWxH) | mm | 8000×4400×3700 (base to highest point) | 8000×4400×3700 (base to highest point) | 8000×4400×3700 (base to highest point) |

| Weight | kg | 14000 | 14000 | 14000 |

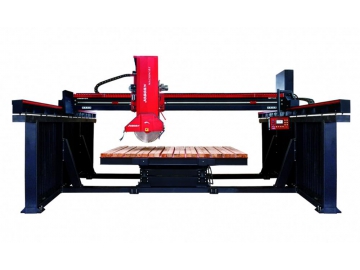

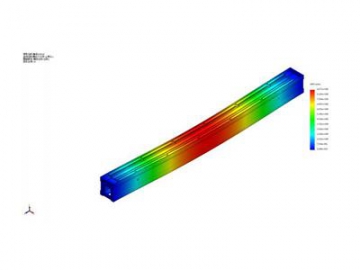

The stress condition of main parts is simulated and calculated by computer software, which is expertly designed.

The side beam guide is V-shaped, which makes the contact surface large, the cutting is steady, and the finished stones are flat. Meanwhile, high precision screws are used to drive the front and back pieces to realize automatic separation.

Controlled by a dual hydraulic system, with a high precision chrome-plated guide pin and wear-resistant guide bush, the guide is tight and wear-resistant. Designed with multi-layer sealing, the guide bush can proof water, dust and oil, which greatly improves its service life.

With a humanized human-computer interaction interface, the cutter saw is simple to operate.

With the blade controlled by dual hydraulic system made in Taiwan to go up and down, the stone equipment works stably.

High efficiency main motor

Adopting German Bosch frequency converter, the bridge saw has a consistent performance.

Used in our customer's factory