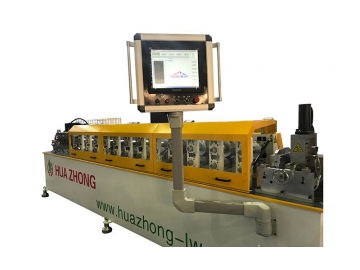

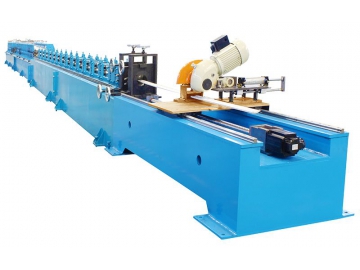

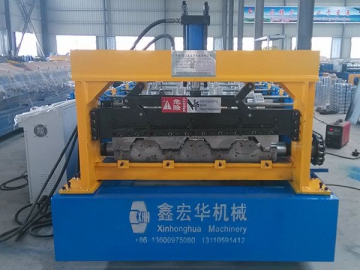

Light Gauge Steel Roll Forming Machine

Suitable for manufacturing metal wall panels insulated with PU/PIR foam

- Uncoiler: 3 tons

- Forming stations: 12 stations

- Thickness: 0.8-1.2mm

- Cutting method: hydraulic cutting

- Drive: gear transmission system

As one of our best-selling pieces of roll forming machinery, the light gauge steel roll forming machine can produce a variety of C and U-shaped sections. We can also customize our light gauge steel roll forming line to meet customers' specific needs.

Samples of Finished Product

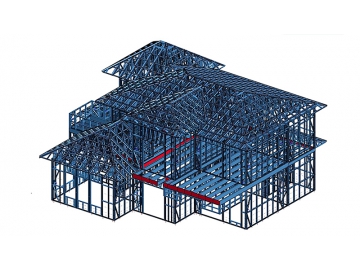

The light gauge steel villa is constructed with cold-formed steel, including walls, floors and roofs. Typically, roll-formed structural C-sections are used to build the construction frame.

- Corrosion Resistance

The typical materials used for light gauge steel frame are galvanized steel sheet or aluminum-zinc alloy coated steel sheet, which has superior corrosion resistance. - Consistent Quality

With the use of stringent manufacturing tolerances, dimensional stability, strength, and straightness of the steel frame are all ensured. - Flexible Design

The construction frames made of steel have greater design flexibility and longer lifespan than wooden components, and can withstand wind load and earthquakes because of the inherent strength of steel. - Good Recyclability

All light gauge steel villa frames contain at least 25% recycled steel.

Steel framing offers several environmental benefits, such as a minimum of 25% recycled steel and 100% recyclable at end of life. - Low Cost, Less Labor Intensity, Easy Installation

The steel frame can be set up to a specific length, thereby greatly lowering labor cost and space waste.

Compared to conventional materials, the steel frame is two thirds lighter. A lighter steel frame can help accelerates the construction progress. Walls can be assembled in a controlled environment, and steel frame can be pre-punched for simple installation of pipes and cables. - Earthquake and Fire Resistant

The scale, frequency, duration and location of natural disasters like earthquakes are all unforeseeable. Therefore, a perfect seismic structure will act in a constant and stable way. The cold-formed steel can completely meet the standard due to the inherent properties of steel and the rigid production procedures of steel frame. - Improved Construction

The steel framing system is a contemporary way for quick and high-quality construction by utilizing light gauge steel structure.

With computer-based precise control, our light gauge steel forming machine can accomplish hole punching to enable the frame and components to be precisely produced.

The design of steel framing system is carried out by using world's leading building design software, Vertex BD Australia. It is versatile design software for designing complete houses, residential buildings, light industrial steel structure and panel fabrication.

Vertex BD comes with all essential functions for creating architectural drawings and building structures, including the ability to add architectural trims, beams, columns, and other elements as well as create walls, doors, windows, roof panels, ceilings, and floors in 2D drawings and 3D models. Additionally, it includes 2D and 3D macros of furniture, appliances, cabinets, and many other accessories that will give your models a new degree of detail.

Huazhong is committed to the innovation of roll forming machines and helping customers lower their costs and stay ahead in their competitive market.