Two Stage Rotary Screw Air Compressor with Single Permanent Magnet Motor Drive

Request a Quote

Description

With a permanent magnet motor, our MDE series two stage rotary screw air compressor with single permanent magnet motor drive has a definite advantage over traditional two stage rotary screw compressor considering its energy savings, high efficiency and low noise.

The main power range is from 132kw to 200kw, the air pressure range is from 6bar to 13bar and the air fow range is from 23.8m3/min to 43m3/min.

Parameters

| Model | Power (kw) | Air Flow/Pressure (m3/min) / (Mpa) | Weight (kg) | Dimension | Pipe diameter of outlet | |||||

| MDE-132A | 132 | 31.1/0.6 | 30.5/0.7 | 28.1/0.8 | 23.8/1.0 | 4160 | 3200*1880*1890 | DN80 | | |

| MDE-160A | 160 | 40.6/0.6 | 38.3/0.7 | 35.7/0.8 | 30.4/1.0 | 4220 | 3200*1880*1890 | DN80 | | |

| MDE-185A | 185 | 40.0/0.7 | 38.5/0.8 | 32.0/1.0 | 28.6/1.25 | 4400 | 3200*1880*1890 | DN80 | | |

| MDE-200A | 200 | 42.5/0.7 | 41.5/0.8 | 37.0/1.0 | 32.0/1.25 | 4700 | 3400*2000*2050 | DN100 | | |

Core components

Permanent magnet airend - The two stage rotary screw air compressor with single permanent magnet motor drive uses a motor with a protection degree of IP54, offering added stability.

- The PM motor and male rotor are directly connected on one shaft, without transmission efficiency loss as it does not require a gearbox and belt.

- The PM motor offers excellent performance and maintains a high degree of efficiency at low frequency and low velocity for higher energy efficiency.

- With the design combination of high performing permanent magnet and special rotor structure, our PM motor's efficiency is 30% better compared to similarly sized induction motors.

- The PM motor is designed with a hermetically sealed construction to prevent the leakage of lubrication.

- The inovance frequency inverter has an optimized structure and outstanding after-sales service network around the world.

- The inovance frequency inverter is easy to use and has high reliability.

- The inovance frequency inverter has a built in braking circuit. It will stop at once and give an alarm the moment any abnormality occurs while the air compressor is running.

- The inovance frequency inverter has high precision speed control under the circumstance of steady speed operation.

- The inovance frequency inverter has a high-speed output under the control of vectors.

- There is a built-in DC reactor to avoid damage of the inovance frequency inverter due to unstable voltage.

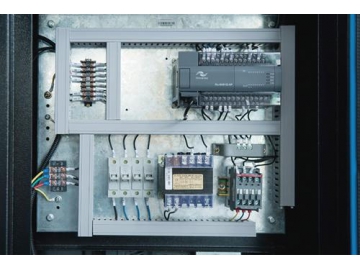

Electrical control

Electrical control Air oil tank

Air oil tank Oil level sight glass

Oil level sight glass

Features

- The same pressure ratio is used at each step of the two stage compression and interstage pressure is set to lower each stage's pressure ratio than single-stage one, which reduces the backflow leakage among rotors and improves the volumetric efficiency and adiabatic efficiency.

- After the first-stage compression, the air is cooled by oil injection in interstage, then reducing the second-stage sucktion temperature. The whole compression is near to a isothermal one, which can reduce the power of compression effectively. In this case, two stage rotary screw air compressor with single permanent magnet motor drive can save 15% energy at same circumstance compared with permanant magnet variable speed two stage rotary screw air compressor with single permanent magnet motor drive.

- It has an intelligent display for easy operation.

- The whole series are equipped with motors of IP54, which has a high protection degree.

- Our products are CE certified.

Principle of energy-saving

- Change the traditional induction motor with high-efficiency technology of permanent magnet rotary screw motor, thus reducing the consumption in transmission.

- Because the gear ratio is fixed, point efficiency is emphasized in this case. That is to say, only with a fixed rotary speed and rated pressure did it have the best specific power. When running in a state of variable speed and variable frequency, considering the fixed speed of gear, interstage pressure will not reach the best one. Rotational speed declining while energy consumption not declining at the same time, it is not suitable for running in variable speed and variable frequency state.

Related products

Send Message

Most Recent

More

Other Products

Videos