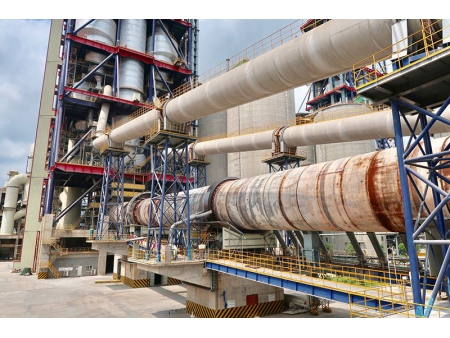

1500 Ton Cement Processing Line

Request a Quote

Based on dry process cement production technique, we have successfully developed this 1500 ton cement processing line. Incorporating a φ3.5×54m rotary kiln, the cement production line is designed with a decomposition furnace and a five-stage cyclone preheater at the kiln tail.

Production Flows

- Limestone crushing

- Crushed limestone pre-homogenization

- Raw mix grinding

- Five-stage cyclone preheating, and decomposition of powdered raw mix

- Cement clinker making in rotary kiln

- Cement grinding

- Cement packaging

Equipment List

| Purpose | Equipment Name / Type / Specification | Production Capacity for Each Piece of Equipment (t/h) | Quantity | Annual Utilization Rate (%) | Remark |

| For limestone crushing | Heavy duty plate feeder Type: B1250×11500mm Feeding size: 800mm Power: 30kW | 200 ~ 350 | 1 | 25.51 | |

Type: TKPC16.18 Feeding size: 800mm Discharging size: ≤25mm Power: 355kW | 250 | 1 | 25.51 | ||

| For limestone pre-homogenization | Stacker-reclaimer Track gauge: 24m Installed gross capacity: 142kW Stacker Material stacking method: Material stacking by continuous luffing and rotation combined movements of boom Number of plies: >400 Reclaimer Material reclaiming method: Recover material from the cross section of the stockpile | Material stacking capacity: 600t/h Material reclaiming capacity: 250t/h | 1 | ||

| For raw mix grinding | Type: HRM2800mm Feeding size: ≤40mm Discharging size: 0.080mm Screen residue of square mesh sieve: 12% Feeding material moisture content: ≤6% Discharging material moisture content: ≤0.5% Motor power: 1,250 kW | 130 | 1 | 60.90 | |

| Waste gas (from rotary kiln and grinding mills) treatment | Humidifier tower Type: Φ7.5×26m Air flow: 400,000m3/h Inlet air temperature: 340℃ Outlet air temperature: 150-220℃ | 1 | 82.19 | ||

| High temperature draught fan Airflow: 400,000m3/h Fan total pressure: 7500Pa Operating temperature: 340℃ (transient temperature: 450℃) Speed: 1450r/min Motor power: 1250kW | 1 | 82.19 | |||

| 2350DIBB24 high temperature draught fan Airflow: 300,000m3/h Fan total pressure: 7500 Pa c.BS930 electrostatic precipitator Processing capacity: 400,000m3/h Inlet dust concentration: ≤80 mg/m3 Outlet dust concentration: ≤50 mg/m3 | 1 | 82.19 | |||

| Kiln tail exhaust fan Airflow: 420,000m3/h Fan total pressure: 1500Pa Operating temperature: 150℃ Motor power: 355kW | 1 | 82.19 | |||

| Cement clinker calcination (kiln tail) | Five-stage cyclone preheater and decomposition furnace Cyclone 1: 2-Φ4300mm Cyclone 2: 1-Φ5600mm Cyclone 3: 1-Φ5600mm Cyclone 4: 1-Φ5900mm Cyclone 5: 1-Φ5900mm Decomposition furnace: Φ6300mm | 62.50 | 1 | 82.19 | |

| Cement clinker production (in kiln) | Type: Φ3.5×54m Production capacity: 1500-1800t/d Inclination: 4% Rotation speed: 0.4 ~ 3.96r/min Motor power: 220kW (DC speed regulation) | 62.50 | 1 | 82.19 | |

| Cement clinker cooling (kiln head) | Grate cooler Type: LBTF1700 | 62.50 | 1 | 82.19 | |

| For cement grinding | Type: Φ3.5×13m Discharging particle size: 320m2/kg Main motor power: 2,000kW | 50 | 2 | 58.59 | |

| Type: O-Sepa1500 Airflow: 1500m3 /min | 2 | 58.59 | |||

| For cement packaging | Measurement precision: ±0.25kg/ bag | 90 | 2 | 34.18 |

Related Names

Cement Production Plant Contractor | Cement Preheater | Cement Production Machines

Related products

Send Message

Most Recent

More

Other Products

Videos