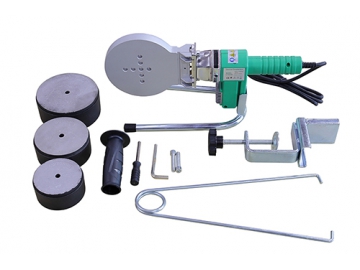

Electrofusion Welding Machine, HJ series

(20mm-1000mm Plastic Pipe Welding)

WELPING HJ series electrofusion welding machine is ideally suitable for butt welding of PE and PP pipes and fittings. It can be used together with various electrofusion fittings. This electrofusion welding machine allows efficient butt welding with complicated pipeline networks and limited space.

- Welding mode: automatic and manual

- Suitable material: PE, PP

- Max. Welding range: 315mm

- Power supply: 170-250V, 40~60 Hz

- Power: 3.5kW

- Ambient temperature: -15~45℃

- Output voltage: 3~70V adjustable

- Output current: 3~60A adjustable

- Output accuracy: ±1.5%

- Control mode: constant voltage/constant current

- Data record: 400

- Duty rate: 60%

- Data interface (optional): scanner, printer

- Welding mode: automatic and manual

- Suitable material: PE, PP

- Max. Welding range: 500mm

- Power supply: 170-250V, 40~60 Hz

- Power: 6.3 kW

- Ambient temperature: -15~45℃

- Output voltage: 3~110V adjustable

- Output current: 3~80A adjustable

- Output accuracy: ±1.5%

- Control mode: constant voltage/constant current

- Data record: 400

- Duty rate: 60%

- Data interface (optional): scanner, printer

- Welding mode: automatic and manual

- Suitable material: PE, PP

- Max. Welding range: 630mm

- Power supply: 170-250V, 40~60 Hz

- Power: 7.5 kW

- Ambient temperature: -15~45℃

- Output voltage: 3~140V adjustable

- Output current: 3~80A adjustable

- Output accuracy: ±1.5%

- Control mode: constant voltage/constant current

- Data record: 400

- Duty rate: 60%

- Data interface (optional): scanner, printer

- Welding mode: automatic and manual

- Suitable material: PE, PP

- Max. Welding range: 1000mm

- Power supply: 170-250V, 40~60 Hz

- Power: 12 kW

- Ambient temperature: -15~45℃

- Output voltage: 3~200V adjustable

- Output current: 3~80A adjustable

- Output accuracy: ±1.5%

- Control mode: constant voltage/constant current

- Data record: 400

- Duty rate: 60%

- Data interface (optional): scanner, printer

| Model | HJ3500 | HJ6300 | HJ7500 | HJ12000 |

| Welding mode | automatic and manual | automatic and manual | automatic and manual | automatic and manual |

| Suitable material | PE, PP | PE, PP | PE, PP | PE, PP |

| Max. Welding range | 315mm | 500mm | 630mm | 1000mm |

| Power supply | 170-250V, 40~60 Hz | 170-250V, 40~60 Hz | 170-250V, 40~60 Hz | 170-250V, 40~60 Hz |

| Power | 3.5kW | 6.3 kW | 7.5 kW | 12 kW |

| Ambient temperature | -15~45℃ | -15~45℃ | -15~45℃ | -15~45℃ |

| Output voltage | 3~70V adjustable | 3~110V adjustable | 3~140V adjustable | 3~200V adjustable |

| Output current | 3~60A adjustable | 3~80A adjustable | 3~80A adjustable | 3~80A adjustable |

| Output accuracy | ±1.5% | ±1.5% | ±1.5% | ±1.5% |

| Control mode | constant voltage/constant current | constant voltage/constant current | constant voltage/constant current | constant voltage/constant current |

| Data record | 400 | 400 | 400 | 400 |

| Duty rate | 60% | 60% | 60% | 60% |

| Data interface (optional) | scanner, printer | scanner, printer | scanner, printer | scanner, printer |

- Inverted structure and the lightweight design for easy carrying and operation;

- Top MCU (Microcontroller Unit) is used as control unit for precise welding operation;

- Voltage regulator used in the electrofusion machine allows for stable welding process;

- Highly qualified industrial-grade electrical parts for better welding performance;

- High-definition LCD screen enables the display of all welding parameters;

- The electrofusion welding machine is easy to operate and durable;

-

-

English operating system is available for control panel and high-definition LCD digital display screen.

Back-lit LCD for time display, and touch-button for easy operation.

-

-

The circuit breaker (made in China) is used together with the IGBT inverter. Automatic voltage stabilization is achieved in the operating process for better welding performance and zero sudden voltage fluctuation.

-

-

The plastic welding machine uses high-quality pure copper wire and multi-functional connectors that are of high temperature resistance and suitable for various interfaces.

-

-

The electrofusion welding machine has a wide range of voltage varying from 150V to 250V. This welding machine has strong adaptability and overpressure protection. Additionally, automatically adjusted temperature-compensated control system allows real-time monitoring of welding status. In this way, abnormal welding can also be adjusted in short time.