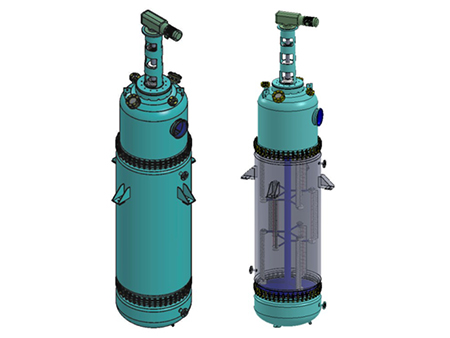

F Type Glass-Lined Reactor

Main Features

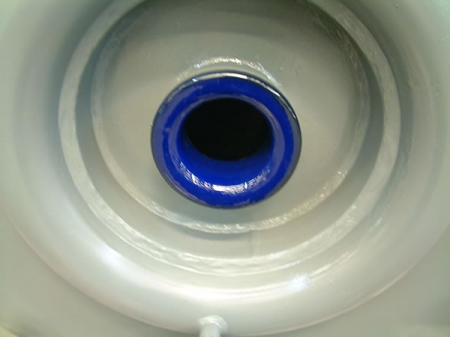

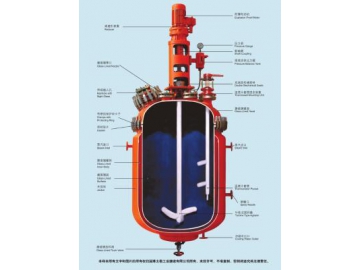

- The F type glass lined reactor comes with a one-piece design that the cover and body can not be separated. Due to that, a manhole has to be designed on the head of the reactor to make it easy for operators to enter the reactor to carry out maintenance and parts replacement.

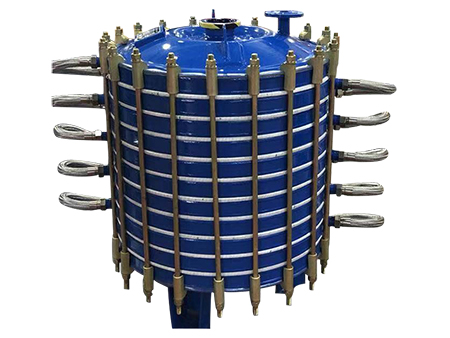

- It is a large capacity industrial process reactor, suitable for large scale production environment.

- Similar to the K-type reactor, this type of chemical reactor is manufactured using TJ09 high end enamel and skilled enameling process. This enables the glass lining to be remarkably corrosion resistant, impact resistant and temperature variation resistant, combined with less prone to fracture and high durability.

- Taiji is able to design and manufacture non standard glass lined reactor to user's requirements.

- Our F type glass lined steel reactor comes in complete specifications, including F1500L, F2000L, F3000L, F4000L, F5000L, F6300L, F8000L, F10000L, F12500L, F16000L, F20000L, F30000L, F50000L, etc.

| Internal Vessel | Jacket | |

| Design Pressure (MPa) | 0.4/0.6/1.0 | 0.6 |

| Design Temperature ( ℃ ) | -19 ℃ /200℃ | -19 ℃ /200℃ |

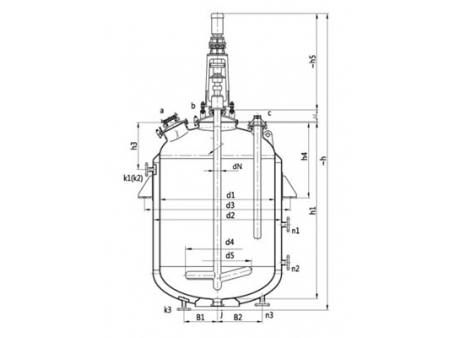

| Symbol | Usage |

| a | Manhole |

| b | Agitator Hole |

| c | Thermowell |

| d, f, g, h | Spare |

| e | Sightglass |

| j | Medium Outlet |

| k1, k2, k3 | In/Outlet |

| n1, n2, n3 | Spray Nozzle |

| m | Vent Hole |

| Unit: mm | |||||||

| Specifications | |||||||

| Nominal Capacity (L) | 1500 | 2000 | 3000 | 4000 | 5000 | 6300 | |

| Total Capacity (L) | 2020 | 2470 | 3860 | 4795 | 6040 | 6900 | |

| Calculated Capacity(Notes 1) (L) | 1990 | 2440 | 3830 | 4795 | 6016 | 6872 | |

| Jacket Capacity (L) | 301 | 390 | 495 | 805 | 898 | 1015 | |

| Heat Exchange Area ( m2 ) | 5.92 | 7.31 | 9.98 | 12.44 | 14.06 | 16.36 | |

| Reference Weight (kg) | 2120 | 2380 | 3360 | 3905 | 4720 | 5200 | |

| Main Dimensions | d1 | 1300 | 1300 | 1600 | 1600 | 1750 | 1750 |

| d2 | 1450 | 1450 | 1750 | 1750 | 1900 | 1900 | |

| d3(Notes 2) | 1622 | 1622 | 1964 | 1964 | 2152 | 2152 | |

| d4 | 680 | 680 | 720 | 720 | 720 | 720 | |

| d5 | 700 | 700 | 800 | 800 | 850 | 850 | |

| h1 | 1801 | 2136 | 2250 | 2730 | 2888 | 3244 | |

| h2 | 190 | 190 | 190 | 190 | 190 | 190 | |

| h3 | 725 | 725 | 700 | 700 | 750 | 750 | |

| h4 | 975 | 975 | 1060 | 1060 | 1200 | 1200 | |

| B1 | 315 | 315 | 315 | 315 | 350 | 350 | |

| B2 | 510 | 510 | 510 | 510 | 510 | 510 | |

| Φ | 30 | 30 | 30 | 30 | 30 | 30 | |

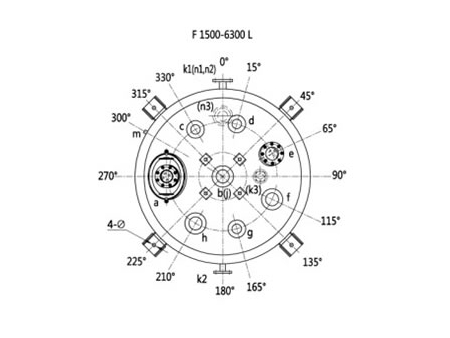

| Nozzle DN | a | 300×400 | 300×400 | 300×400 | 300×400 | 300×400 | 300×400 |

| b | 125 | 125 | 150 | 150 | 150 | 150 | |

| c | 100 | 100 | 100 | 100 | 125 | 125 | |

| d | 100 | 100 | 100 | 100 | 125 | 125 | |

| e | 125 | 125 | 125 | 125 | 125 | 125 | |

| f | 125 | 125 | 125 | 125 | 150 | 150 | |

| g | 100 | 100 | 100 | 100 | 125 | 125 | |

| h | 125 | 125 | 125 | 125 | 150 | 150 | |

| j | 100 | 100 | 125 | 125 | 125 | 125 | |

| Jacket Nozzle DN | k1 | 40 | 40 | 65 | 65 | 65 | 65 |

| k2 | 40 | 40 | 65 | 65 | 65 | 65 | |

| k3 | 40 | 40 | 65 | 65 | 65 | 65 | |

| n1 | 50 | 50 | 65 | 65 | 65 | 65 | |

| n2 | / | / | / | 65 | 65 | 65 | |

| n3 | 50 | 50 | 65 | 65 | 65 | 65 | |

| m | G3/8" | G3/8" | G3/8" | G3/8" | G3/8" | G3/8" | |

| Drive | DN | 80 | 80 | 95 | 95 | 95 | 95 |

| h5 | 1320 | 1320 | 1360 | 1360 | 1360 | 1530 | |

| Notes 1: Calculated Capacity: Volume under highneck flange. | |||||||

| Notes 2: Types of support depend on users; if there is no special request, lugs would be normally applied. | |||||||

| Inner Vessel | Jacket | |

| Design Pressure (MPa) | 0.4/0.6/1.0 | 0.6 |

| Design Temperature ( ℃ ) | -19 ℃ /200℃ | -19 ℃ /200℃ |

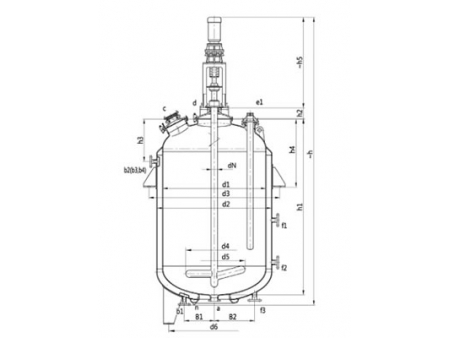

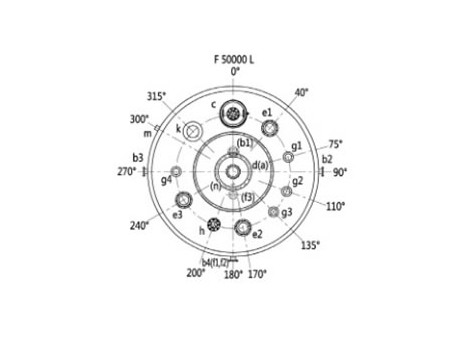

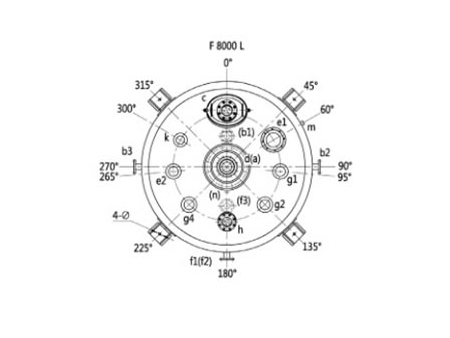

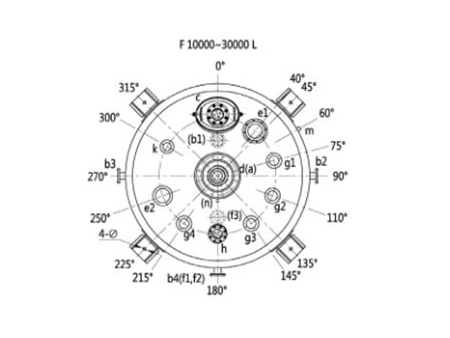

| Symbol | Usage |

| a | Medium Outlet |

| b1,b2,b3,b4 | In/Outlet |

| c | Manhole |

| d | Agitator Hole |

| e1 | Thermowell |

| e2, g1, g2, g3, g4, k | Spare |

| h | Sightglass |

| m | Vent Hole |

| n | Clean Hole |

F50000L Nozzle Design (Plan View)

F50000L Nozzle Design (Plan View) F8000L Nozzle Design (Plan View)

F8000L Nozzle Design (Plan View) F10000L~F30000L Nozzle Design (Plan View)

F10000L~F30000L Nozzle Design (Plan View)| Unit: mm | ||||||||

| Specifications | | | | | | | | |

| Nominal Capacity (L) | 8000 | 10000 | 12500 | 16000 | 20000 | 30000 | 50000 | |

| Total Capacity (L) | 9105 | 11719 | 13696 | 17491 | 21835 | 33645 | 56444 | |

| Calculated Capacity(Notes 1) (L) | 9060 | 11674 | 13651 | 17446 | 21790 | 33500 | 55514 | |

| Jacket Capacity (L) | 1666 | 1940 | 2243 | 2551 | 2870 | 3700 | 4520 | |

| Heat Exchange Area ( ㎡ ) | 18.38 | 21.35 | 24.89 | 29.48 | 34.04 | 45 | 34.04 | |

| Reference Weight (kg) | 6959 | 7911 | 9342 | 11222 | 13530 | 19270 | 34590 | |

| Main Dimension | d1 | 2000 | 2200 | 2200 | 2400 | 2600 | 3000 | 3800 |

| d2 | 2200 | 2400 | 2400 | 2600 | 2800 | 3200 | 4000 | |

| d3(Notes 2) | 2452 | 2703 | 2703 | 2908 | 3179 | / | / | |

| h1 | 3310 | 3533 | 4053 | 4346 | 4641 | 5340 | 5611 | |

| h2 | 210 | 210 | 210 | 210 | 210 | 260 | 647 | |

| h3 | 850 | 900 | 900 | 950 | 1000 | 1150 | 1340 | |

| h4 | 1200 | 1300 | 1300 | 1400 | 1550 | / | / | |

| h | 5400 | 5600 | 6530 | 7010 | 7475 | 8835 | 10425 | |

| B1 | 400 | 470 | 470 | 470 | 470 | 470 | 470 | |

| B2 | 510 | 550 | 550 | 550 | 550 | 550 | 550 | |

| Φ | 30 | 36 | 36 | 36 | 36 | / | / | |

| Nozzle DN | a | 125 | 150 | 150 | 150 | 150 | 150 | 150 |

| c | 300×400 | 300×400 | 300×400 | 450 | 450 | 450 | 450 | |

| d | 200 | 200 | 200 | 200 | 250 | 250 | 250 | |

| e1 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | |

| e2 | 150 | 200 | 200 | 200 | 200 | 200 | 200 | |

| e3 | / | / | / | / | / | / | 200 | |

| g1 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | |

| g2 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | |

| g3 | / | 150 | 150 | 150 | 150 | 150 | 150 | |

| g4 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | |

| h | 125 | 125 | 125 | 125 | 125 | 125 | 125 | |

| k | 125 | 125 | 125 | 125 | 125 | 125 | 125 | |

| Jacket Nozzle DN | b1 | 65 | 80 | 80 | 100 | 100 | 100 | 125 |

| b2 | 65 | 80 | 80 | 100 | 100 | 100 | 125 | |

| b3 | 65 | 80 | 80 | 100 | 100 | 100 | 125 | |

| b4 | / | 80 | 80 | 100 | 100 | 100 | 100 | |

| f1 | 65 | 80 | 80 | 100 | 100 | 100 | 100 | |

| f2 | 65 | 80 | 80 | 100 | 100 | 100 | 100 | |

| f3 | 65 | 80 | 80 | 100 | 100 | 100 | 100 | |

| m | G3/4" | G3/4" | G3/4" | G3/4" | G3/4" | G3/4" | G3/4" | |

| n | G1/2" | G1/2" | G1/2" | G1/2" | G1/2" | G1/2" | G1/2" | |

| Drive | DN | 110 | 110 | 110 | 130 | 140 | 160 | 160 |

| h5 | 1375 | 1375 | 1375 | 1995 | 2190 | 2420 | 2640 | |

| Notes 1: Calculated Capacity: Volume under highneck flange. | ||||||||

| Notes 2: Support types could be determined by users; if there is no special request, lugs would be normally applied. | ||||||||

- No.100, Taishan Road, New Century Industrial Park, Guoli, Huantai District, Zibo City, Shandong Province

- 86-533-8409960

- 86-15053366638

- 15053366638

Taiji has decades of experience in the construction and delivery of glass-lined equipment for chemical, pharmaceutical, food processing industries, etc. We are certified for the fabrication of glass-lined products by ASME, PED and RTN. As an experienced glass-lined vessels manufacturer, we understand the selection, layout and manufacturing of glass lined process equipment and their spare parts is critical for the reliability of their production as well as essential for the secure process and storage of corrosive, poison and dangerous chemicals. Therefore, our glass lined steel equipment such as glass-lined reactor and storage tank, pressure vessel is the long-recognized standard in the chemical process industries. Taiji has the capability to adapt our services to your individual requirements.