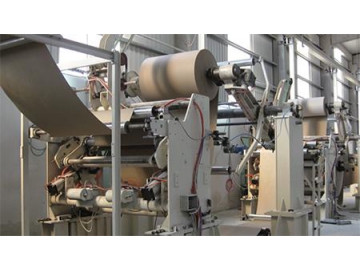

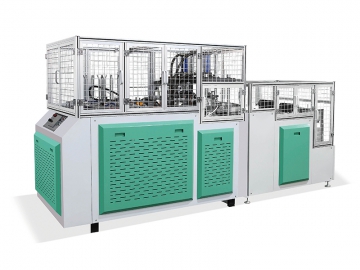

Cardboard Preparation and Forming Unit of Plasterboard Production Line

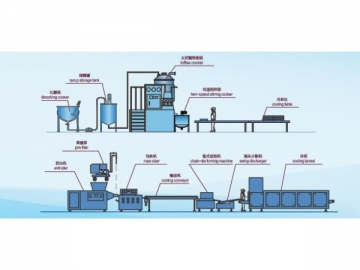

During the procedure of cardboard preparation and forming unit, mixed raw material are formed into an even sandwich structure along with cardboards.

Cardboard preparation and forming unit consists of cardboard preparation unit, rectifying machine, creasing unit, vertical mixing unit, forming machine, etc.

Three types of cardboard preparation methods and optional

Manual:

Consists of paper roll stand, sheeting laying table, paper storage device, drawing-out device, tensioning device, adjusting device, etc.;

Semi-Auto:

Consists of full-auto paper layer, etc. Mature technologies in paper industry and applied.

Full-Auto:

Consists of full-auto paper layer, etc. Mature technologies in paper industry and applied.

A unique air shaft, a paper tension adjustable magnetic particle pneumatic brake, accurate sheet laying method, and a precision electro-hydraulic automatic rectifying machine are applied in the cardboard preparation system, those above along with the creaser, do a great effort to the trimming and shaping processes, and partly assure the appearance and quality of the plasterboards.

Our mixing units are made of wear resistant stainless steel, which grants better durability.

Mixing process of water, gypsum powder, additives, etc. is performed in the procedure of this unit.

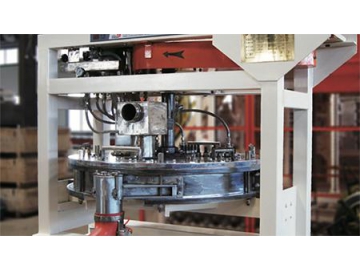

LVJOE’s self-developed vertical mixing unit applies relatively accurate screw metering pump, and intuitive liquid flowmeter, which provide great convenience, and is able to place slurry stably on bottom cardboard. The unit is also able to avoid slurry from caking during mixing process.

①Dry/wet feedings are accurately controlled by PID;

②One-key preset formula switching;

③Settings and feedback data are recorded and filed in master computer, able for visualized analysis and management such as sketching trend graphs.

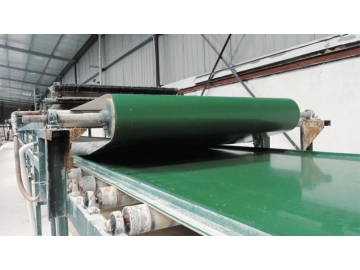

Creasing unit is applied for edgefold process on bottom cardboard, thickness of folded edge is the thickness of the plasterboard.

Slurry on bottom cardboard is made even during the procedure of forming machine.

LVJOE offers multiple types of forming machine for the needs of different production powers, latest types are able for plasterboard thickness and evenness adjustment manually or via remote control.

Automatic Control:①Automatic control forming machine, high slurry stability.

②Convenient one-key switch on/off.