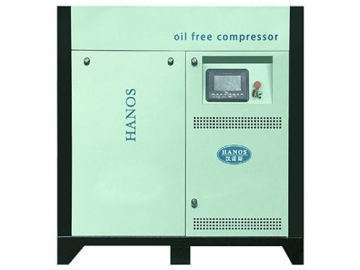

Oil-injected Rotary Screw Integrated Compressor

Request a Quote

Features

- The direct drive oil-injected rotary screw compressor features long-hour stable running, and can offer 24-hour stable compressed air supply.

- 100% duty cycle;

- Flexible and quiet operation;

- Energy saving, cost effective;

- Long maintenance period, long lifespan;

- Integrated design, no internal pipes and connectors;

- 380V/3HP/50HZ power source, IEC standard design;

- Air cooling structure grants the compressor the ability to work at under 40℃ environmental temperatures. This allows it to run for a full-day.

- The compressor is equipped with automatic on/off controls, constant speed controller, and relay.

- The compressor applies maintenance-convenient direct drive structures. There is no need for replacing the belt and other consumable transmission parts.

- Designed with an air storage tank

Benefits of Direct Drive

- Efficiency

The direct drive transmission and gear drive transmission offer 98%-99% of transmission efficiency while the belt transmission offers 94%-98% of efficiency. - No load Power Consumption

The unloaded pressure for compressor with gear drive transmission is over 2.5bar, with some are even up to 4bar. The unloaded pressure for the direct drive and belt transmission can be 0 in theory. This is because the oil absorbed by rotor is enough to lubricate rotor and bearings. For safety, the unloaded pressure of compressor with direct drive and belt transmission is kept around 0.5bar. - Pressure changing for installed air compressor

When the operation conditions change, designed pressure of an installed air compressor might be inappropriate, then we may need to change the pressure of the installed compressor. For a gear drive air compressor, changing its pressure is difficult and expensive; for a direct drive one, it could be easier. For a belt drive one, the work could be very easy. You only need to change pulley and belt to change the pressure of the compressor. - Maintenance cost

All oil-injected rotary screw compressors apply annular shaft seals, which need to be replaced after their lifespan. For direct drive and belt drive compressors, replacing the seal only needs to require the taking off of the coupling or pulley.

For gear drive compressors, this process is different. When motor or rotor bearing is damaged, related important parts usually get damaged directly or indirectly. That issue doesn’t exist for direct drive or belt drive air compressors.

Technical Parameters

| Model | JF-10AT | JF-15AT | JF-20AT |

| Pressure | 0.8Mpa | ||

| Displacement Volume(FAD) | 1 .05m³/min | 1.52m³/min | 2.3m³/min |

| Total Package Input Power | 8.78kw/m³/min | 7.98kw/m³/min | 8.71kw/m³/min |

| Cooling Method | Air Cooling | ||

| Outlet Temperature | ±12℃ (ambient temperature) | ||

| Motor Power | 7.5kw | 11kw | 15kw |

| Motor Speed | 1470r/min | 2900r/min | 2920r/min |

| Power Supply | 380V/3PH/50HZ | ||

| Motor Starting Method | Direct on-line Starting | Y-△ Starting | |

| Insulation Class of Main Motor | F | ||

| Protection Level of Main Motor | Ip54 | IP23/lp54 | IP23/IP54 |

| Applicable Temperature Range | -5~ 450℃ | ||

| Transmission | Direct Drive | ||

| Noise Level | 62±2dB(A) | 64 ± 2dB(A) | 66 ± 2dB(A) |

| Oil Content in a Compressed Air | ≤3ppm | ||

| Coolant Capacity | 4.5L/compressor | 9L/compressor | |

| Air Tank | 130L | 145L | 150L |

| Air Outlet Size | G½'' | G¾'' | |

| Weight | About 275kg | About 450kg | About 480kg |

| Dimensions | 1000x700x1270mm | 1050x750x1400mm | 1050x750x1380mm |

Related products

Send Message

Most Recent

More

Other Products

Videos