MSE Series Permanent Magnet Rotary Screw Air Compressor

Request a Quote

Description

The main power range of our MSE series variable speed rotary screw air compressor is from 7.5kw to 250kw and the air delivery ranges from 0.92m3/min to 45m3/min. The compressor's air pressure ranges from 6 bar to 10 bar.

Our MSE series rotary variable speed screw air compressor can meet the various needs of customers no matter the application.

The MSE series rotary screw air compressor has the advantage of compact structure, low noise and energy-efficiency. These units are widely used in machinery, light industry, textile, food production and handling, petroleum, chemical industry, metallurgy, mining, electric power, urban construction, medical research and other industrial applications.

Parameters

| Model | Power | Air delivery/discharge pressure | Pipe diameter of outlet | |||||

| (kW) | (m3/min)/(Mpa) | |||||||

| MSE7.5A | 7.5 | 1.31/0.6 | 1.13/0.7 | 1.11/0.8 | 0.92/1.0 | / | G3/4 | |

| MSE11A | 11 | 2.17/0.6 | 1.74/0.7 | 1.70/0.8 | 1.45/1.0 | / | G1 | |

| MSE15A | 15 | 2.89/0.6 | 2.29/0.7 | 2.21/0.8 | 1.96/1.0 | / | G1 | |

| MSE22A | 22 | 4.08/0.6 | 3.76/0.7 | 3.69/0.8 | 3.09/1.0 | / | G11/4 | |

| MSE30A | 30 | 6.18/0.6 | 5.72/0.7 | 5.39/0.8 | 4.68/1.0 | / | G11/2 | |

| MSE37A | 37 | 7.45/0.6 | 6.87/0.7 | 6.65/0.8 | 5.67/1.0 | / | G11/2 | |

| MSE45A | 45 | 9.27/0.6 | 8.78/0.7 | 8.46/0.8 | 7.39/1.0 | / | G21/2 | |

| MSE55A | 55 | 11.65/0.6 | 10.00/0.7 | 9.90/0.8 | 8.54/1.0 | / | G21/2 | |

| MSE75A | 75 | 14.37/0.6 | 13.35/0.7 | 13.25/0.8 | 11.77/1.0 | / | G21/2 | |

| MSE90A | 90 | 19.11/0.6 | 17.72/0.7 | 16.31/0.8 | 14.08/1.0 | / | DN65 | |

| MSE110A | 110 | 21.92/0.6 | 20.12/0.7 | 20.05/0.8 | 16.65/1.0 | / | DN65 | |

| MSE132A | 132 | 27.01/0.6 | 23.73/0.7 | 23.54/0.8 | 20.85/1.0 | / | DN65 | |

| MSE250A | 250 | 45.00/0.6 | 44.00/0.7 | 43.00/0.8 | 38.50/1.0 | 35.00/1.25 | DN100 | |

Core components

- PM motor and male rotor are directly connected on one shaft, without transmission efficiency loss because the machine does not require a gearbox or belt.

- The PM motor has excellent performance and maintains high motor efficiency at low frequency and low velocity operation.

- With the design combination of high performance permanent magnet and special rotor structure, our PM motor's efficiency is 30% greater compared to induction motors of the same size.

- The PM motor has an independent air-cooled cooling system, no need for additional cooling systems.

- The stator of the motor uses a corona-resistant enameled wire which is specially designed for frequency converters, and features excellent insulating properties and a long service life.

- The PM motor is designed with a special hermetically-sealed construction, which prevents leakage of lubricating oil.

- The Inovance frequency inverter doesn't need to be directly connected to the power grid, enabling quick and easy installation.

- The inovance frequency inverter has a high-speed output under the control of vectors, offering high precision under the circumstance of steady speed.

- There is a built-in DC reactor.

- The inovance frequency inverter has a built in braking circuit.

- The inovance frequency inverter has a global after-sales service network.

Main engine

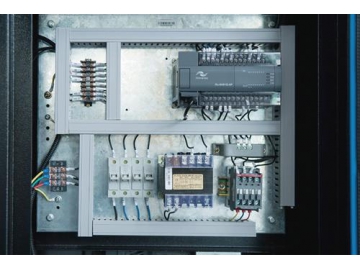

Main engine Electrical control

Electrical control Internal structure

Internal structure Air oil tank

Air oil tank Oil level sight glass

Oil level sight glass

Features

- The MSE series rotary screw air compressor is equipped with a permanent magnetic-synchro screw airend created by MOAIR independently, which can save up to 15% energy compared with common asynchronous frequency conversion screw compressors and 30% energy compared with common screw compressors.

- With a soft starting method, the instant values of electric current when the motor starts is largely declined, which can protect the motor and other parts of the air compressor.

- The structure of the whole machine is designed to be more compact, saving much space. Also the volume of permanent magnet synchronous motor is twice smaller than that of common motor.

- The whole design is more reasonable for insulating the oil circuit and electrical components, which turns out to be more safe.

- The combination of Teflon hose and steel pipe reduces vibration and noise effectively

- With high-efficiency permanent magnet, the life of permanent magnet motor is more than 15 years.

- With intelligent display, users can watch the real time running of the unit. What's more, simple and convenient operation will give you comfort while using it.

- The MSE series rotary screw air compressor has a high degree of protection and we can offer you products with protection of IP23 and IP51.

- Our products are CE certified.

Energy-saving principle

- Using the technology of high-efficiency permanent magnet synchronous motor and changing traditional induction motor, we have a patented design of our product with 100% transmission efficiency.

- Perfectly matched with converter, our air compressor can change speed automatically to keep best running state and reduce energy loss.

Related products

Send Message

Most Recent

More

Other Products

Videos