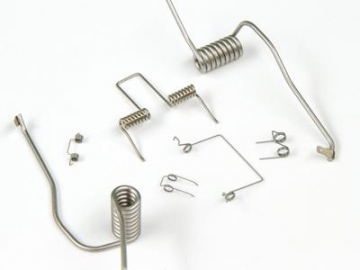

Torsion Springs

Torsional springs are classified into two types: single torsion and double torsion. The spiral spring is the one that uses a torque, or stores rotational energy. A torsion spring is traditionally mounted around a shaft or pivot supported by three or more points, and are easy to install thanks to the variety of end types available.

Torsional springs are mainly used in curtains, door hinges and electrical appliances. Wires used to make these springs are often rectangular or circular in shape, while the curved rectangular wire is able to effectively withstand stress.

Spring materialsKLF chooses torsion spring material according to the spring application, weather, temperature and other factors, and primarily uses brass and stainless steel as the raw materials. We can also treat these springs with zinc plating, chromium plating, nickel plating, tin plating, copper plating and other surface treatments.

| Shape and size | End type | Material |

| * Single torsion * Double torsion * Special torsion * Wire diameter: 0.1-6.0mm | * Bending * Hooked * Tortile * Special customized | * Carbon steel wire * High carbon steel wire * Stainless steel wire * Nickel plating stainless steel wire |

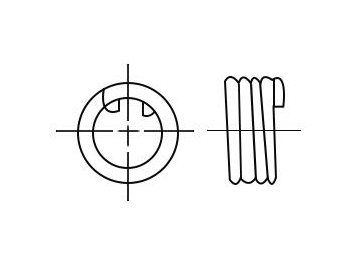

Stainless Steel Torsion Spring for Switches

Wire diameter: 2.8mm

Material: Stainless steel

Recommended application: Switches

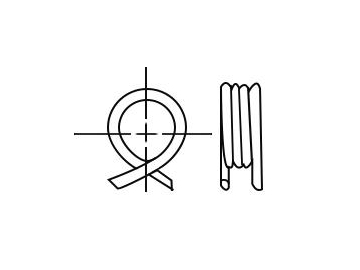

High Carbon Steel Torsion Spring for Water Dispenser

Wire diameter: 1.2mm

Material: High Carbon Steel Wire

Application: Water dispenser

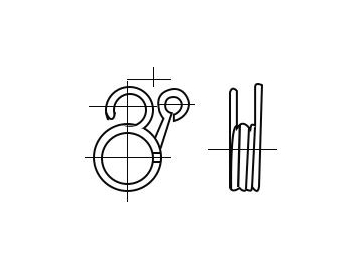

Stainless Steel Torsion Spring for Clothespins

Wire diameter: 1.5mm

Material: Stainless steel

Recommended application: Clothespins

Stainless Steel for Torsion Spring for Fan

Wire diameter: 0.4mm

Material: Stainless steel

Recommended application: Fan

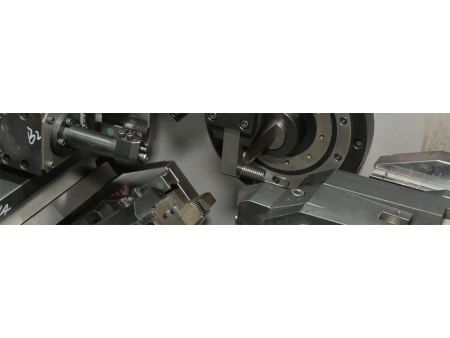

KLF designs and manufactures mechanical spring according to the requirements listed below, and uses a camless spring former, milling machine, grinding machine and other production equipment.

- Spring material

- Wire diameter

- Outer diameter (O/D), Inner diameter (I/D), Middle diameter (M/D)

- Length L, length A, length B

- Rotation and cycles

- Free angle

- Surface electroplating and other treatment

- Torsional moment parameters and testing conditions (optional)

- Service life requirements (optional)

- Tolerances and working conditions

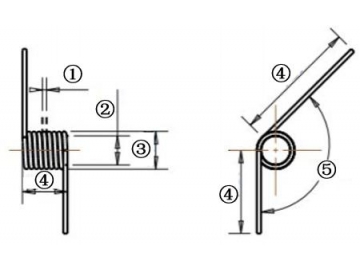

- ①wire diameter

- ②inner diameter

- ③outer diameter

- ④length

- ⑤free angle

End type

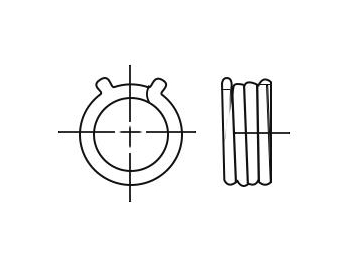

Short hook ends

Short hook ends  Straight offset ends

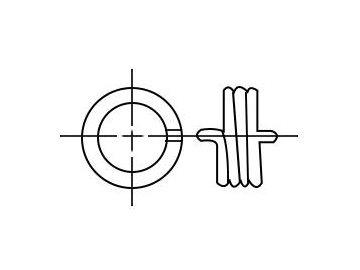

Straight offset ends  Double torsion

Double torsion  Hinge ends

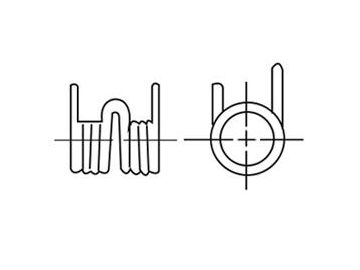

Hinge ends  Straight torsion ends

Straight torsion ends  Special ends

Special ends

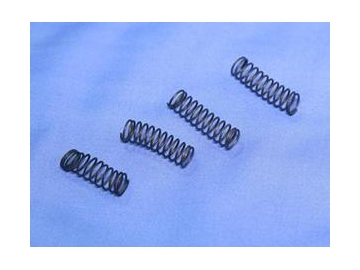

KLF customizes a variety of torque springs, with the following being common specifications in regards to size, material, and manufacturing specifications. For customization information, please contact us directly.