Hot Water Shower Sterilizer

Hot Water Sterilizer (for infusion products)

Model:

YXQ.SG Series

Application Range

Infusion packed in soft plastic bag, plastic bottle, glass bottle

Sterilizing Principle and Advantage

1. Sterilizing medium: hot circulating water

2. Mode: spraying water (top & side spraying)

3. Advantage: When compared to steam sterilization, the temperature distribution is more uniform, has no cooling point, and a wide setting range for temperature (above 80°C). Circulating water runs in a sealed chamber and piping, which avoids re-contamination during the cooling phase.

4. The hot water spraying mode regulates temperature and pressure changes, ensuring complete sterilizing results and the shape of the infusion bag.

5. Control mode: PLC Touch screen, easy for operation and monitor.

Safety System

The sterilizer has the multiple safety structures, including overpressure protection, door interlock system, electric overload and short circuit protection, all to guarantee safe operation.

Main Structure

The sterilizer mainly consists of the chamber, door, control system, and piping system.

Chamber

1. The chamber is made of SS304. It is designed and manufactured according to the China standard GB-150 STEEL PRESSURE VESSEL, supervised by the national technical inspection department in China. It is firm and durable.

2. The chamber has an over-pressure safety device, which is safe and reliable.

3. Design pressure: 0.27Mpa

4. The inner chamber automatic system can avoid operator safety problems and contamination, because the trolley is driven automatically by inner chains.

5. GMP validation joint.

Doors

1. Double sliding doors, made of SUS 304

2. Automatic door structure: The door is open and closed by an electric motor, which is driven by a reducing gear.

3. The doors are sealed by inflatable gasket filled with compressed air. The gasket is made of silicon rubber. (company patent)

4. It has an interlock system.

a. Doors cannot open when in operation.

b. When the steam pressure in the chamber is over 0.027MPa, the door cannot open.

c. The front door and the back door cannot open at the same time to ensure the isolation.

Insulation layer

Chamber covered by rock wool of 80mm to avoid heat emission.

Decoration Cover

Horizontal rectangular frame, made of stainless steel, easy to clean

Control System

1. The control system is mainly composed of PLC and touch screen from Mitsubishi.

2. The whole system operates in a reliable manner and controls are precise, guaranteeing the overall performance and sterilizing effect.

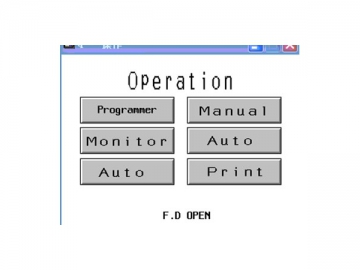

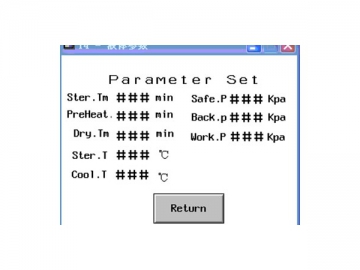

3. The touch screen displays parameters like temperature, pressure, time, and F0. Users can choose programs (automatic and manual mode), and set sterilizing parameters on touch screen, which also displays parameters and the cycle phases, as well as print sterilizing reports.

4. The whole system has over current, over loading and leaking power protection systems.

5. PC: Displays parameters like temperature, pressure, time, F0, operator and batch number and monitor software, all developed by our own company. It is easy to operate, and a user familiar with Windows software can easily operate the equipment after training.

- Monitoring Screen

- Parameter Screen

- Parameter Screen

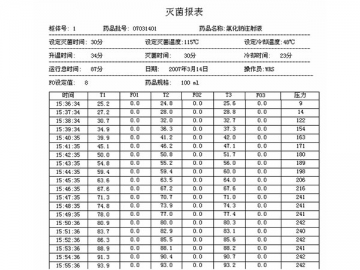

Sterilizing Report

Real-time sterilizing report can be printed by printer, data cannot be changed, ensuring the reality.

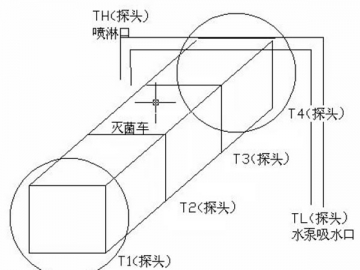

View for Temperature Sensor Place

There are temperature sensors for inner temperature test, ensuring uniform temperature distribution and sterilizing result.

Sterilizing Process

1. The sterilizing process is mainly composed of water-in, heat, sterilize (stay same temperature for a certain time), and cool phases. Users can set sterilizing parameters according to item characteristics and process requirements. The setting range of sterilizing parameters is:

a. Sterilizing Pressure: 0.07-0.23Mpa

b. Sterilizing Temperature 80-134℃

c. Sterilizing Time: 1-99 minutes

2. Special sterilizing programs can be set according to the user's requirements.

Process Description

Start set water level

Automatic test (utility and state) → water in →water inner circulation → eat → sterilize → cool → pressure relief →water out → end

Process curves (for reference)

Pipeline System

1. The pipeline system is composed of the control valve, heat exchanger, pipes and filters. It also features energy transfusion, heat exchange, and controlling channels of the sterilizer.

2. The control valve is a pneumatic valve, which has the advantages of a strong heat resistance performance, reliable operation and low fault rate, which will ensure the overall performance of the sterilizer.

3. The pipelines are connected by stainless steel pipes. It uses hoop fitting, which is easy for installation, maintenance and inspection.

4. The pipeline is polished, smooth and easy to clean.

5. Two parts for circulation: inner and outer circulation.

a. Inner part: channels for sterilizing medium, mainly for water pump, heat exchanger, and spraying device.

b. Outer part: channels for heating and cooling, mainly connected by valves and pipes.

6. The heat exchanger uses a plate-type exchanger, which has the excellence of high heat exchanging efficiency and easy maintenance.

Spraying Device

1. Three-side spraying mode (top, and two sides)

2. Advantage: three-side spraying mode can spray water evenly, ensuring contact between the soft bag and hot water, and reduce the temperature balancing time between top and bottom (4 minutes).

Loading Ways of Goods: Inner trolley

Transport mode

1. Inside chamber -- automatic system

An automatic system at the bottom of the chamber consists of a stainless steel wheel and chain, on which the trolley moves.

2. Outside chamber -- rails and lift, platform and turn plate