Capsule Fill Machine, Type NJP-1200D

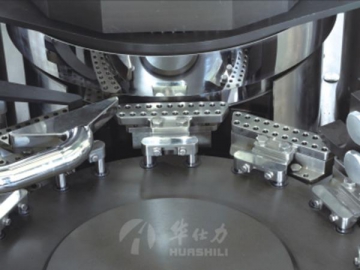

The NJP-1200D capsule fill machine is a newly developed piece of equipment from Wisely. The capsule filling machine is equipped with an independent capsule conveying mechanism, which uses an integrated modular mechanism that is easy to assemble and clean.

Application:

This capsule fill machine is used for simultaneous filling of different medicines, including powders, pellets, tablets, fixed-number pellets, powders+pellets, powders+tablets,pellets+tablets and more.

| Max Output | 72000 capsule/h |

| Suit for Capsule Size | 00#-5#and secure type capsule A-B |

| No. of Mold Bores | 9 |

| Machine dimensions (including the electric control cabinet) | 980x980x2100mm |

| Net Weight | 1000kg |

| Power | 380/220V 50/60Hz 7kw |

| Noise | < 70dB |

- The independent capsule conveying mechanism is fully enclosed, thus preventing capsules from unnaturally falling into segments, and ensuring normal system operations.

- We can achieve uniform distribution of medicine powders in the powder storage room, ensure the correct flow direction and smooth flow speed, and finally, achieve an extremely accurate medicine filling accuracy.

- The integrated modular structure makes it possible for users to finish the machine assembly, using only 6 integrated modules, thus avoiding any assembly defects that result from poor operator handling.

- The NJP-1200D Precise Weighing Automatic Capsule Fill Machine uses an integrated modular and highly precise turntable, which is small in size, features a light load and a long service life.

- A full set of molds and all components that need daily cleaning and maintenance are all equipped with positioning pins. The connection and fastening methods between various components are extremely light and simple. All the specifications of the fastening tools are of a unified standard, so that users only need a small wrench to carry out assembly/disassembly.

- For some re-run that start after the mold disassembly or equipment maintenance, we offer a handheld remote control to control the inching and machine testing, which is convenient to operate and ensures personnel safety.

- All gas pipelines interfaces are equipped with standard clamps that are easily to load, unload and clean.

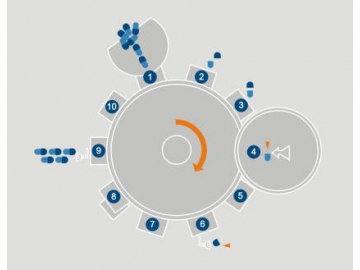

- Capsule sorting and separating

- Upper mold separation

- Lower mold separation

- Powder filling or pellets canning via a fixed or adjustable metering panel

- Reserved workstation

- Waste capsule removal

- Reserved workstation

- Capsule sealing

- Capsule ejecting

- Molds cleaning

WISELY offers a wide range of pharmaceutical machinery like capsule filling machines, tablet polishers, and pharma packaging machines. The company was founded in 1992 and is a member of the China Association for Pharmaceutical Equipment. We participate in continuous development and have many patents for technologies used in our capsule fillers. We provide customers with high quality pharmaceutical and medical equipment all over the world.

Related:

Pharmaceutical Packaging Machinery, Medicine Packaging Machine, Pill Capsule Machine, Capsule Filling Line, Automatic Capsule Filling Machine, Pill Capsule Filler, Pill Filler Machine, Automatic Capsule Machine, Pharmaceutical Packaging Equipment