2-layer Air Bubble Film Extrusion Line

Pansatec's 2-layer air bubble film extrusion line is configured with single-screw extruder or twin-screw extruder. The bubble film line with twin-screw extruder can provide higher production efficiency and better productivity.

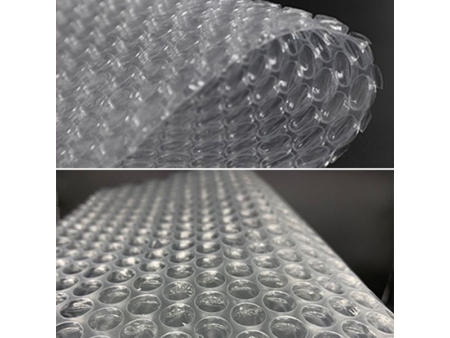

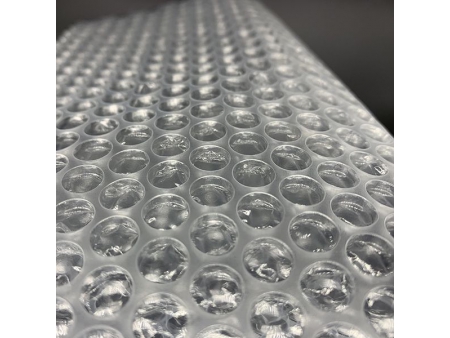

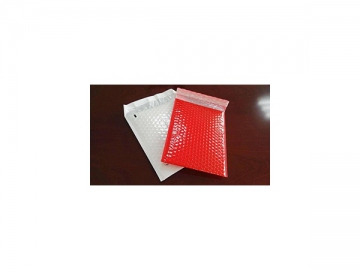

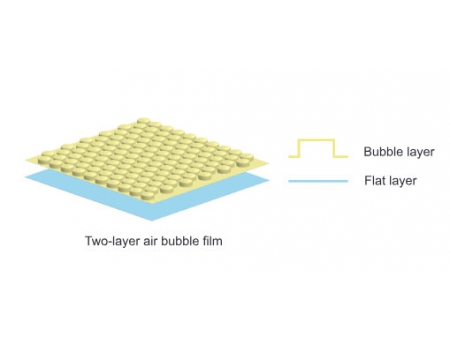

The produced air bubble film consists of two layers of polyethylene, one layer of flat film and one layer of air-filled hemispheres (bubbles), can be widely used in fields of parcel delivery and packaging. Thanks to its features of low cost, rapid payback, high efficiency and low power consumption, this air bubble film extrusion line is quite suitable for newcomers who have just entered the bubble film industry.

In contrast to other air bubble film lines that are equipped with single-screw extruder in the domestic market, Pansatec's 2-layer air bubble film line can produce bubble film with thickness up to 25GSM, which is characterized by excellent resistance to shock and abrasion.

- T-die and rolls are constructed with high grade steel and precisely processed with an error less than 0.05mm, the steel rolls are non-stick and hard to deform, and robust enough to withstand continuous manufacturing process;

- Produced bubble film features high resistance to bursting, the thickness can reach 25GSM;

- Temperature control and transmission system are all from world's renowned brands, ensuring 24-hour smooth and continuous operation;

- Machine structure is made from high strength steel panel, greatly enhancing the stability and precision;

- Good investment payback, the service life of this extrusion line is more than 10 years;

- The operation workflow can be extremely simplified, allowing user to operate the equipment with only one-hour training, significantly reducing labor cost;

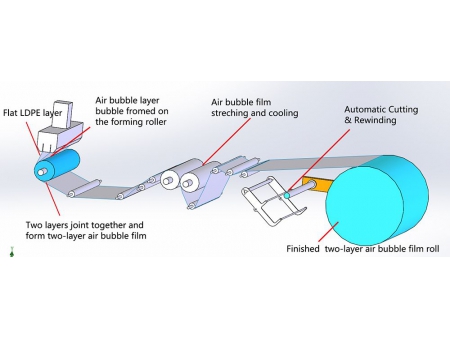

- Flat LDPE layer

- Air bubble layer (air bubbles are formed by using forming roll)

- Joining two layers together to form 2-layer air bubble film

- Air bubble film stretching and cooling

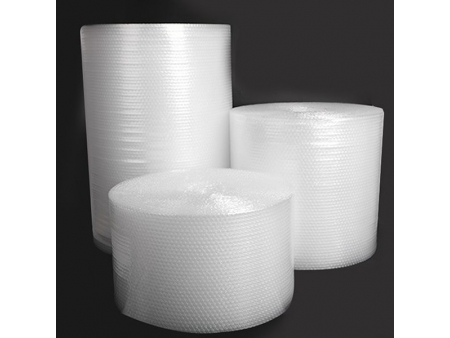

- Automatic cutting and rewinding

- Finished 2-layer air bubble film roll

Model: PT-L2S1-W1200

Bubble film width (mm): 1200

Material: LDPE/LLDPE

Line speed (m/hr): 600-2100

Capacity (kg/hr): 50-70

Thickness (g/m2): 25- 300

Screw diameter (mm): Φ75

Heating power (kW): 37

Operation power (kW): 25

Installation power (kW): 56

Dimension (L×W×H)(m): 7×2.0×2.5

Weight (kg): 3500

Model: PT-L2S1-W1600

Bubble film width (mm): 1600

Material: LDPE/LLDPE

Line speed (m/hr): 600-2100

Capacity (kg/hr): 60-80

Thickness (g/m2): 25- 300

Screw diameter (mm): Φ75

Heating power (kW): 48

Operation power (kW): 34

Installation power (kW): 74

Dimension (L×W×H)(m): 7×2.4×2.5

Weight (kg): 4500

Model: PT-L2S1-W2000

Bubble film width (mm): 2000

Material: LDPE/LLDPE

Line speed (m/hr): 600-2100

Capacity (kg/hr): 70-95

Thickness (g/m2): 28- 300

Screw diameter (mm): Φ85

Heating power (kW): 60

Operation power (kW): 38

Installation power (kW): 92

Dimension (L×W×H)(m): 8×2.8×2.5

Weight (kg): 5000

Model: PT-L2S1-W2600

Bubble film width (mm): 2600

Material: LDPE/LLDPE

Line speed (m/hr): 600-2100

Capacity (kg/hr): 90-130

Thickness (g/m2): 30- 300

Screw diameter (mm): Φ90

Heating power (kW): 68

Operation power (kW): 50

Installation power (kW): 107

Dimension (L×W×H)(m): 9×3.4×2.5

Weight (kg): 7000

Model: PT-L2S1-W3000

Bubble film width (mm): 3000

Material: LDPE/LLDPE

Line speed (m/hr): 600-2100

Capacity (kg/hr): 100-180

Thickness (g/m2): 34-300

Screw diameter (mm): Φ110

Heating power (kW): 81

Operation power (kW): 68

Installation power (kW): 130

Dimension (L×W×H)(m): 10×3.8×2.5

Weight (kg): 9000

| Model | PT-L2S1-W1200 | PT-L2S1-W1600 | PT-L2S1-W2000 | PT-L2S1-W2600 | PT-L2S1-W3000 |

| Bubble film width (mm) | 1200 | 1600 | 2000 | 2600 | 3000 |

| Material | LDPE/LLDPE | LDPE/LLDPE | LDPE/LLDPE | LDPE/LLDPE | LDPE/LLDPE |

| Line speed (m/hr) | 600-2100 | 600-2100 | 600-2100 | 600-2100 | 600-2100 |

| Capacity (kg/hr) | 50-70 | 60-80 | 70-95 | 90-130 | 100-180 |

| Thickness (g/m2) | 25- 300 | 25- 300 | 28- 300 | 30- 300 | 34-300 |

| Screw diameter (mm) | Φ75 | Φ75 | Φ85 | Φ90 | Φ110 |

| Heating power (kW) | 37 | 48 | 60 | 68 | 81 |

| Operation power (kW) | 25 | 34 | 38 | 50 | 68 |

| Installation power (kW) | 56 | 74 | 92 | 107 | 130 |

| Dimension (L×W×H)(m) | 7×2.0×2.5 | 7×2.4×2.5 | 8×2.8×2.5 | 9×3.4×2.5 | 10×3.8×2.5 |

| Weight (kg) | 3500 | 4500 | 5000 | 7000 | 9000 |

Model: PT-L2S2-W1200

Bubble film width (mm): 1200

Material: LDPE/LLDPE

Line speed (m/hr): 600-2100

Capacity (kg/hr): 65-120

Thickness (g/m2): 25-300

Screw diameter (mm): Φ65(x2)

Heating power (kW): 53

Operation power (kW): 32

Installation power (kW): 85

Dimension (L×W×H)(m): 8×2.5×2.5

Weight (kg): 4000

Model: PT-L2S2-W1600

Bubble film width (mm): 1600

Material: LDPE/LLDPE

Line speed (m/hr): 600-2100

Capacity (kg/hr): 75-130

Thickness (g/m2): 25-300

Screw diameter (mm): Φ65(x2)

Heating power (kW): 60

Operation power (kW): 42

Installation power (kW): 92

Dimension (L×W×H)(m): 8×2.9×2.5

Weight (kg): 4700

Model: PT-L2S2-W2000

Bubble film width (mm): 2000

Material: LDPE/LLDPE

Line speed (m/hr): 600-2100

Capacity (kg/hr): 100-175

Thickness (g/m2): 28-300

Screw diameter (mm): Φ75(x2)

Heating power (kW): 78

Operation power (kW): 49

Installation power (kW): 124

Dimension (L×W×H)(m): 9×3.3×2.5

Weight (kg): 5800

Model: PT-L2S2-W2600

Bubble film width (mm): 2600

Material: LDPE/LLDPE

Line speed (m/hr): 600-2100

Capacity (kg/hr): 115-180

Thickness (g/m2): 30-300

Screw diameter (mm): Φ80(x2)

Heating power (kW): 92

Operation power (kW): 63

Installation power (kW): 154

Dimension (L×W×H)(m): 10×3.9×2.5

Weight (kg): 7800

Model: PT-L2S2-W3000

Bubble film width (mm): 3000

Material: LDPE/LLDPE

Line speed (m/hr): 600-2100

Capacity (kg/hr): 135-220

Thickness (g/m2): 32-300

Screw diameter (mm): Φ90(x2)

Heating power (kW): 105

Operation power (kW): 86

Installation power (kW): 199

Dimension (L×W×H)(m): 11×4.3×2.5

Weight (kg): 9900

| Model | PT-L2S2-W1200 | PT-L2S2-W1600 | PT-L2S2-W2000 | PT -L2S2-W2600 | PT-L2S2-W3000 |

| Bubble film width (mm) | 1200 | 1600 | 2000 | 2600 | 3000 |

| Material | LDPE/LLDPE | LDPE/LLDPE | LDPE/LLDPE | LDPE/LLDPE | LDPE/LLDPE |

| Line speed (m/hr) | 600-2100 | 600-2100 | 600-2100 | 600-2100 | 600-2100 |

| Capacity (kg/hr) | 65-120 | 75-130 | 100-175 | 115-180 | 135-220 |

| Thickness (g/m2) | 25-300 | 25-300 | 28-300 | 30-300 | 32-300 |

| Screw diameter (mm) | Φ65(x2) | Φ65(x2) | Φ75(x2) | Φ80(x2) | Φ90(x2) |

| Heating power (kW) | 53 | 60 | 78 | 92 | 105 |

| Operation power (kW) | 32 | 42 | 49 | 63 | 86 |

| Installation power (kW) | 85 | 92 | 124 | 154 | 199 |

| Dimension (L×W×H)(m) | 8×2.5×2.5 | 8×2.9×2.5 | 9×3.3×2.5 | 10×3.9×2.5 | 11×4.3×2.5 |

| Weight (kg) | 4000 | 4700 | 5800 | 7800 | 9900 |