Energy Saving Roller Mill

Description

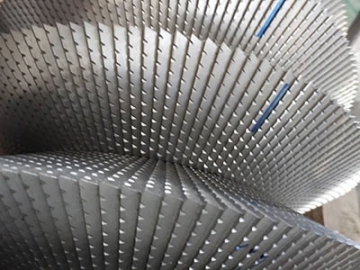

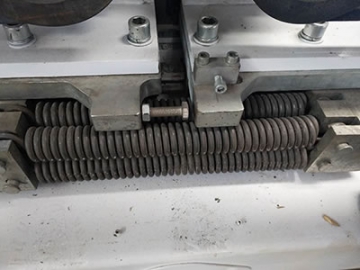

This series energy saving roller mill is designed with dual roller crushing technology, utilizing the speed difference and the knife face of the cutter tooth to shear and crush the materials. The cutter body has large moment of inertia and is possessed with energy storage function itself, which greatly reduce the electricity consumption in the animal feed production process. The overall energy saving rate exceeds 25%, so that the problem of cost control for an animal feed enterprise is successfully solved. Meanwhile, this roller mill does not require a negative pressure fan to be equipped. The super long service life together with the efficient performance make it perfectly suitable for large output feed processing enterprises with an hourly output of 10~60tons.

Application

This grinder machine is suitable for crushing raw grain, traditional Chinese herbal medicine, meat and bone meal, tobacco stem and chemical raw materials etc. It can reach a fineness of 15~40 mesh, widely applied to the production of chicken feed and pig feed.

| Model | Power(kw) | Yield(t/h) | Weight(kg) | L*W*H(m) |

| FSDD22*30 | 11*2 | 22 | 2800 | 1.4*1.0*1.0 |

| FSDD22*48 | 15*2 | 30 | 3600 | 1.8*1.0*1.0 |

| FSDD30*60 | 30*2 | 62 | 4200 | 2.2*1.5*1.5 |

1. The cutter head for crushing materials is made of imported super wearable alloy, of which the service life is 6 times that of high chrome alloys.

2. The design principle of the whole machine can be adapted to different working conditions.

3. This roller mill covers an area of 3 m2, while traditional hammer crushers cover 10 m2. Thus, the use of our grinder machine can remarkably reduce the plant construction cost.

4. Traditional crushers can meet the grain rolling requirements only after going through two-stage crushing and suction peeling. The roller mill only requires one-stage crushing and one-stage suction peeling to make the peeling rate of soybeans reach 95% above.