Rapid prototype features

Features

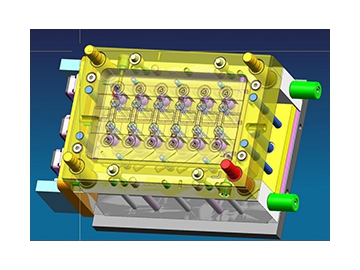

- Ability to manufacture three-dimensional products of any complex shape.

- Product strength can achieve the same strength as aluminum materials.

- Noticeable parting line at the mold joints

- Rapid molding has a higher precision and smaller limitations on the dimensions. Consistent deviation is achieved, allowing for batch delivery

- Rapid molding uses metals that are durable and applicable in injection molding for 10 to 20000 times. Furthermore, complex metal parts can also be manufactured.

- Fully automated process where the products can be electroplated, textured, EDM or welded.

- Directly driven by CAD model, therefore achieving a complete integration of design and manufacturing. Thus, its intelligence and easy modification offer a great design environment in order to generate the perfect product design.

- When compared to the traditional mold making, the molding process needs no specific fixtures, molds and cutting tools. This lowers project costs and the time needed for production. Rapid molding departments will offer injection molded end products that are in full accordance with customer supplier CAD designs within 12 to 15 days.

If you are looking for rapid prototyping services, kindly follow here for more info.

Related products

Send Message

Most Recent

More

Other Products

Videos