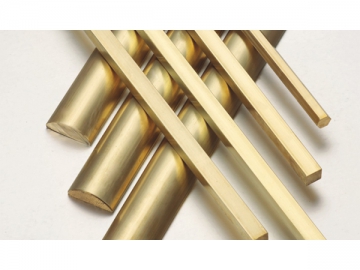

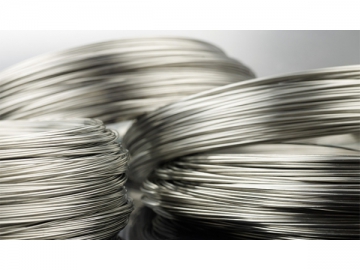

Brazing Alloy / Filler Metal

Request a Quote

The welding & brazing alloy produced by Powerway Alloy features high strength and corrosion resistance. This filler material is widely used in brass oxyacetylene welding, carbon arc welding, universal type oxyacetylene welding, argon arc welding and steel material MIG welding.

Categories: Bar & Wire production-Brazing Material

Name: Brazing Material / Filler Material

Number: RBCuZn-C, RBCuZn-D, BCu60ZnSn-R, CuSn, CuSi3, CuAl8

Alloy Features

Welded joints have amazing strength performance;

Mobility and air tightness are excellent;

Solder joints are formed without pores, the weld surface is smooth;

Good corrosion resistance;

| Articles | Characteristics | ||||||

| Name | GB | AWS | DIN | Melting point ( ℃) | Specification (mm) | Characteristics | |

| CuZn40Fe 1Sn1MnSi | RBCuZn -C | CuZn40 FeSiSn | 860 | 900 | 0.8-9.0 | Universal oxy-acetylene brazing filler material with mobility that can effectively control the evaporation of zinc | |

| BCu60ZnSn -R | - | CuZn40Sn1 | 870 | 910 | Good fluidity, high-strength for gas welding and carbon arc welding of brass | ||

| BCu48ZnNi -R | RBCuZn -D | CuNi10Zn40 | 890 | 950 | High welding strength, good fluidity | ||

| HSCuAl | ERCuAl-A1 | CuAl8 | 1030 | 1040 | Excellent corrosion-resistance in seawater, corrosion-resistance to acid | ||

| HSCuSi | ERCuSi -A | CuSi3Mn1 | 910 | 1025 | Excellent machinery performance. Argon arc welding of copper alloys and MIG brazing of steel | ||

| HSCu | ERCu | CuSn1MnSi | 1030 | 1054 | The welding spot is firm with excellent air tightness. | ||

Notes: Manufacturing can be customized based on specific requirements.

Related products

Send Message

Most Recent

More

Other Products

Videos