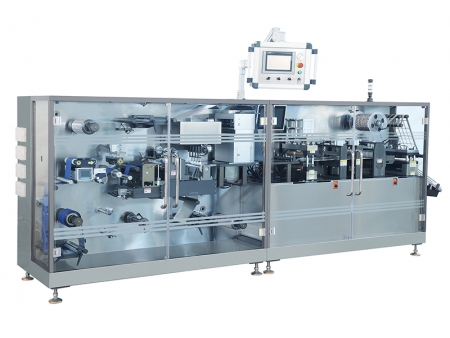

Strip Packaging Machine

Strip packaging machines are a pharmaceutical packaging machine that utilize aluminum foil and film laminates as the packaging material. They are used to package tablets, capsules, and pills, including hard capsules, soft capsules, circular tablets, coated tablets, irregular tablets and more. Each machine features a high packing speed, a high yield and excellent tightness, with the highest packaging speed of 4,000 pcs/minute.

The SHW series of strip packaging machines are developed, fabricated and innovated here in house, backed by expert experience within the pharmaceutical industry. It features a number of functions, including differentiated strip rejection, material cooling, remote monitoring and more. What’s more, the strip packaging machine can be combined with tablet presses, sifters, cartoning machines and more to form a complete production line. The exterior of the aluminum foil strip packaging machine is made of 304 stainless steel, while parts that come into direct contact with material is made of 316L stainless steel for a smooth, easy to clean, and corrosion resistant surface that will have no chemical reaction or stick to the pharmaceutical products.

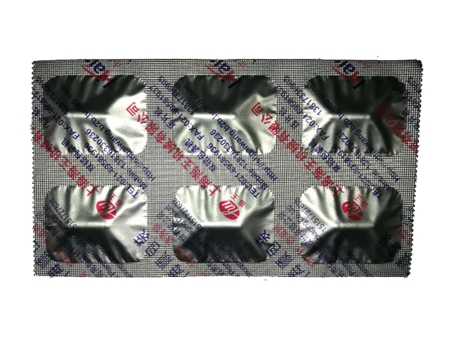

Packing samplesBelow are eight kinds of pharmaceutical packaging machines with different specifications that we’ve produced for previous customers. Users can either order the products shown below directly, or contact HaiWang about what you need to pack, and your requirements, after which we will recommend the best strip packaging machine or customized pill packaging machine to meet your needs.

- The molds and feeding track of the aluminum foil packaging machine are all standardized, and allow for a quick change between interchangeable parts that are adaptable to packaging products in different specifications.

- The packaging sizes and quantities are adjustable within 25 different options for convenient storage and usage.

- The excellent package tightness ensures medicine lasts longer under warranty.

- The stainless steel fabricated body is smooth, easy to clean and sterilize, and corrosion resistant, ensuring there is no chemical reaction or attachments between the machine and medicine.

- The high quality photoelectric components ensure the quality and long packaging machine service life, ensuring they meet requirements for a low energy cost, high output, noiseless operation, and frequency control.

- Easy to operate and maintain with GMP certification.

- Material drag

The material drag's precision has an important influence on the size, evenness, and tightness of product packaging.

- Feeding

The contact parts on the feeder are all made of 316L stainless steel or are surface treated, ensuring medicine will not stick to the feeder or other substances. The water cooling system maintains a constant medicine temperature, protecting it against heat caused by heat sealing, and guaranteeing a smooth feeding process.

- Water Cooling

The plate with blue pipes is the cold plate with circulating water, which removes heat from the feeding plate, and thus preventing medicine discoloration or deformations caused by high temperatures.

- Air Cooling

In addition to the water cooling system, the strip packaging machine is also equipped with an air cooling system to ensure a fast cool down, effectively retaining the shape and effectiveness of medicine.

- Heat Sealing

- Heat sealing roller

- Heating pipe

The interior of the heat sealing roller is a high power heating pipe that makes the sealing faster, better and smoother.

- Tension control

The strip packaging machine is equipped with two sets of tension control device to ensure the package evenness and smoothness.

- Waste collection

In order to maintain clean packages, medical companies trim package edges, which must be collected in order to keep the working environment clean.

- Differentiated strip rejection

Every fiber represents a medicine channel equipped with a specific signal amplifier to reject any incorrect feeding.

- AllHaiWang products feature a one year limited warranty.

- The products can be returned or changed in one month if any problems arise due to a poor product quality.

- HaiWang will follow all product conditions for life.

- Use the products according to the instructions, and if non-consumable parts become damaged during the warranty period, HaiWang will provide fittings and installation services free of charge.

- HaiWang provides installation and training services after the purchase is complete.

- Time needed for service: 10 working days in visa required countries in Asia, 15 working days for other countries and regions.

Processing pharmaceuticals requires precision and efficiency and this includes the packaging of these products. HaiWang Machinery Co. has been specializing in designing and manufacturing high-quality pharmaceutical packaging equipment since 2000. As a common type of pharmaceutical equipment, the strip packaging machine is widely used for packing capsules, pills, tablets, etc. HaiWang is a pharmaceutical equipment manufacturer with 2 decades of experience in the pharmaceutical equipment industry, we are able to provide you pharmaceutical machines with reliable qualiy. In order to better serve our customer, we employ more than 20 agents in over 20 countries and regions all over the world.

Strip Packing Machine, Strip Packaging, Pharma Packaging Solutions, Pharma Machine, Packaging Solutions, Pharmaceutical Packaging Equipment