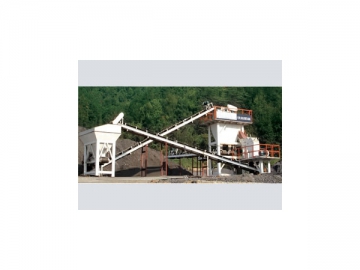

RAP Breaking and Screening System

RAP Breaking and Screening System

Descriptions of RAP Breaking & Screen System

Batching bin or Aggregate batcher

1 Arching device prevents the materials being blocked in the bin.

2. Proper feeding conveyer ensures a stable mixing capability

3. Well-known brand speed reducer provides stable and balanced power

Charging Conveyer and Discharging Conveyer

1. Low-end receiving bin ensures the recycled materials will not spill

2.Rear wear-resistant cleaner allows the drum to work more stably.

3. Conveyer is controlled by reliable specialized pullswitch, which does improve the safety of the equipment

4. A heavy block is installed on the front cleaner to prevent the recycled materials from attaching to the conveyer.

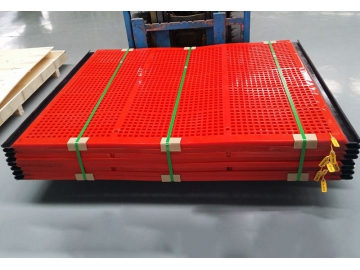

Screening or sieving

1. Maintenance-free sieve (adopt OLI vibration motor of Italy technology) driving device reduces maintenance costs.

2. Uniquely designed tension structure for the sieve makes it faster to change sieves.

3. Domestic famous high manganese wear-resistant sieve prolongs its service time.

4. Totally-enclosed structure efficiently reduces the powder pollution.

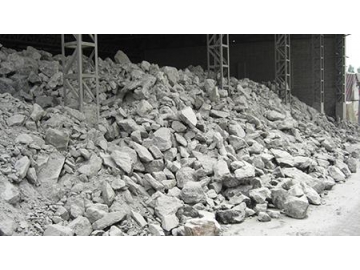

Breaking

1. The lining board is cushioned by spring, which will not destroy original grade of the recycled materials because of cracking.

2. High chrome wear-resistant and impact-proof block and lining board do help prolong the service time of the breaker.

3.Unique device installed to stop aggregates from scattering while breaking

Technical Parameters of RAP Breaking & Screen System

| Model No. | PLZ-30 | PLZ-60 |

| Throughput | 30T/h | 60T/h |

| Silo conveyer power | 5.5KW | 5.5KW |

| Anti-Bridging power | 0.55KW×2 | 0.55KW×2 |

| Charging conveyer power | 5.5KW | 5.5KW |

| Returning conveyer power | ------ | 5.5KW |

| Vibration sieve power | 5.5KW | 5.5KW |

| Breaker power | 22KW | 37KW |

| Discharging conveyer power | 4KW | 4KW×2 |

| General power | 50KW | 75KW |