Air Compressor Welding Solution

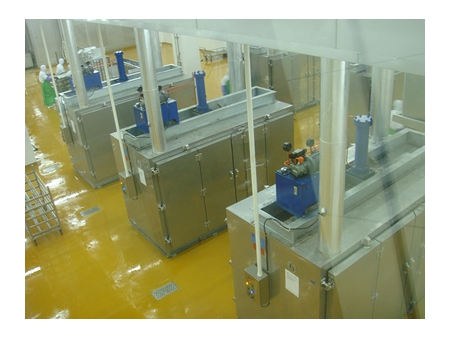

Air compressor welding automation system

| Item | Height | Length | Width |

| Size | 2800 | 8900 | 9000 |

| Item | Parameter |

| Rated capacity (KVA) | 440KVA-Five sets, 660KVA- One set |

| Power supply (V/¢/HZ) | 380/ 3 /50 |

| Primary current (A) | 350;500 |

| Rated duty cycle (%) | 20 |

| Secondary empty voltage (V) | 10.4 |

| Cylinder stroke (mm) | 150 |

| Welding speed (s/piece) | 7 |

| Max. welding pressure (kgf) | 1500,2500 |

| compressed air pressure (MPa) | 0.6~0.7 |

| Compressed air consumption(0.5MPa air pressure, stroke:100mm) (L/once) | 160 |

| Cooling water consumption (L/MIN) | 130 |

| Primary cable specification (MM2) | 50MM2 -5 sets; 70MM2-1 Set |

| Max. Short Circuit Current( KA ) | 60;85 |

Feature

1. The fridge air compressor welding automation system is equipped with an automatic feeding copper pipe system and connection terminal auto feed.

2. Equipped with two sets of KUKA robotic conveying systems.

3. The welding machine is specially designed for box body automatic welding operations.

Background information

Due to high labor costs in the compressor production industry, we have combined automatic feeding, welding, and conveying systems in the welding process of fridge air compressor production. It can be integrated into fully-automatic manufacturing lines.

Air compressor copper pipe and bracket robot welding workstation

| Item | Height | Length | Width |

| Size | 2500 | 3350 | 7000 |

| Item | Parameter |

| Rated capacity (KVA) | 660 165 |

| Power supply (V/¢/HZ) | 380/ 3 /50 |

| Primary current (A) | 500 |

| Rated duty cycle (%) | 20 |

| Secondary empty voltage (V) | 10.4 |

| Throat depth (mm) | 340 |

| Arm gap (mm) | 122 |

| Cylinder stroke (mm) | 150 |

| Welding speed (s/piece) | 12 |

| Max. welding pressure (kgf) | 2454 (air suction pipe);1000 (bracket) |

| compressed air pressure (MPa) | 0.6~0.7 |

| Compressed air consumption(0.5MPa air pressure, stroke: 60mm) (L/once) | 28 |

| Cooling water consumption (L/MIN) | 24 |

| Primary cable specification (MM2) | 3*70 2*16 |

| Max. Short Circuit Current (KA) | 85 (air suction pipe);30 (bracket) |

Feature

1. The welding system is equipped with an air suction pipe automatic welding system.

2. Comes equipped with a mounting bracket automatic welding system.

3. Robotic conveying system for optimal efficiency.

Background information

Due to high labor costs within the production process of compressor products, Heron has combined automatic feeding, welding, and conveying systems in the welding process of fridge air compressor production. It can be integrated into fully-automatic manufacturing lines.

Compressor conduit welding machine

| Item | Height | Length | Width |

| Size | 3000 | 1800 | 1940 |

| Item | Parameter |

| Rated capacity (KVA) | 660 |

| Power supply (V/¢/HZ) | 380/ 3 /50 |

| Primary current (A) | 500 |

| Rated duty cycle (%) | 20 |

| Secondary empty voltage (V) | 10.4 |

| Throat depth (mm) | 310 |

| Arm gap (mm ) | 105 |

| Cylinder stroke( mm ) | 150 |

| Welding speed (s/piece) | 7 |

| Max. welding pressure (kgf) | 2500 |

| compressed air pressure (MPa) | 0.6~0.7 |

| Compressed air consumption(0.5MPa air pressure, stroke: 60mm) (L/once) | 14.43 |

| Cooling water consumption (L/MIN) | 24 |

| Primary cable specification (MM2) | 3*70 2*16 |

| Max. Short Circuit Current (KA) | 85 |

Feature

1. Fridge air compressor conduit welding machines are equipped with 660KVA MFDC projection welding units.

2. The welding equipment is equipped with air suction pipe auto-feeding systems.

3. The welding system is outfitted with a manual barrel feeding process.

Background information

For our conduit welding machine we have combined automatic feeding, welding, and conveying systems in the welding process of fridge air compressor production. It can be integrated into fully-automatic manufacturing lines.

Top and bottom cover of liquid accumulator welding machine

| Item | Height | Length | Width |

| Size | 2750 | 3950 | 3150 |

| Item | Parameter |

| Rated capacity (uf) | 120000 |

| Power supply (KVA/V/¢/HZ) | 135/380/3/50 |

| Primary current (A) | 210 |

| Rated duty cycle (%) | 50 |

| Secondary empty voltage (V) | 27-30 |

| Secondary voltage regulating series | 2 |

| Cylinder stroke( mm) | 150 |

| Max. welding pressure (kgf) | 10000 |

| compressed air pressure (MPa) | 0.6~0.7 |

| Compressed air consumption(0.5MPa air pressure, stroke: 60mm) (L/once) | 14.43 |

| Cooling water consumption (L/MIN) | 10 |

| Primary cable specification (MM2) | 50 |

Feature

1. The top and bottom cover of the liquid accumulator welding machine is outfitted with a 120KJ medium voltage capacitor discharge welding unit.

2. The welding system is equipped with a gas-liquid force-cylinder pressurization system.

3. Gate-type body mechanism.

Background information

Fridge air compressors with liquid accumulators are typically constructed form components that undergo a brazing process in a furnace, which requires a large production center with high amounts of energy consumption. Now, we utilize electric resistance technology and the welding process can be finished in seconds, saving energy and time.