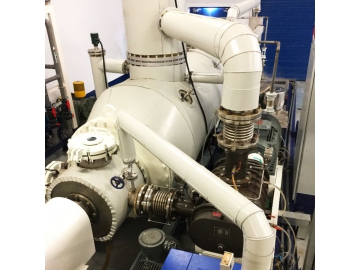

Double-Effect/Multi-Effect Falling Film Evaporator

The double effect/multi-effect falling film evaporator is commonly utilized for the processing of starch, glucose, monosodium glutamate, Western medicine, and traditional Chinese medicine. The concentrator is indispensable to industries such as dairy and chemical. Our device is especially designed for the vacuum concentration of heat sensitive substances within low temperature environments. It is capable of continuous sterilization and concentration procedures. The contraption has been professionally designed and optimized to include features and benefits that its predecessor lacked. We have reduced material heating durations by maintaining a low temperature ambience. The machine subtly influences product color, flavoring, and nutrient composition. The effects of this phenomenon are more apparent in procedures such as the concentration of milk and other heat sensitive substances.

- Multiple functions have been implemented with the release of our double effect/multi-effect falling film evaporator. For instance, the boiler is capable of reclaiming materials repetitively with the circulation of primary, secondary, and tertiary effects. Materials can be fed continuously or at intervals into the machine for processing.

- All components that come into physical contact with raw materials, secondary steam, or condensed water are crafted from stainless steel. We utilize premium steel that are in conformation with GMP standards. Both the heater and evaporator are composed of heat preservation structures. Stainless sheet steel is utilized as a shell for heat retention. The surface can be mirror polished or treated for a matte finish.

- The heating chamber adopts a grounded structural design. It has a streamlined exterior and is easy to install, operate, and maintain.

- A low-noise water ring pump is utilized to provide traction for the vacuum. The pump is compact and features superb suction power with the benefit of low water and energy consumption.

- Advanced design structure eliminates the need for an external return flow, effectively preventing the repeated heating of materials and completely resolving the issue of pipe clogging.

- The hot pressure pump operates with low steam consumption and minimal noise. The device has a steam/gauge pressure of 0.8MPa and an extraction coefficient of 0.98.

- A reliable structural composition allows for the establishment of a stable vacuuming system.

- The CIP cleaning system is provided; it is capable of fully cleaning the evaporator without the need for machine disassembly.

- The machine settings may be adjusted according to client side specifications. Configurable components include the automatic control system for discharge concentration, sterilization temperature, and tank level balancing. Additionally, the ice water refrigeration system can be calibrated as well.

- The double effect/multi-effect falling film evaporator has a uniquely designed structure. Concentration yields are both even and thick. Raw materials can be processed without air pockets while being sealed, greatly reducing material waste and pollution. The concentrated yields do not agglomerate, allowing for easy cleaning. The top and bottom cover can be opened, granting easy access for maintenance. One person is sufficient for the of undertaking of this task.

As a China-based double-effect/ multi-effect falling film evaporator manufacturer and supplier, Jiadi provides a broad range of products, including fully automatic CIP system, cassava concentration machine, plate type pasteurizer (3 stages), continuous water soaking sterilizer, and more.

Related Names

Multiple Function Milk Powder Evaporator | High Efficiency Milk Evaporation | Evaporator for Dried Milk Manufacturing