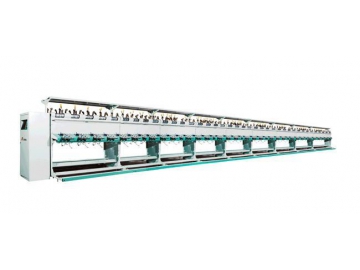

Cone Yarn Precision Winding Machine

The BW32 cone yarn precision winding machine can be used for dying winding, warp separation and rewinding of the short fiber and synthetic or regenerated filament. It can also be used for rewinding, whether that requires oil or not. This machine features an outstanding dying and rewinding performance, with the winding method divided into both precise winding and digital winding.

Count range: 10-3000 dtex

Yarn diameter: up to 280 mm

Full roll weight: up to 8kg

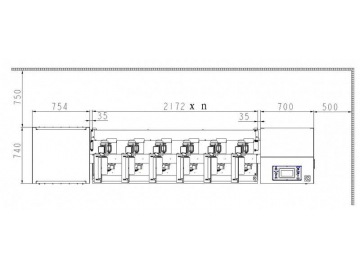

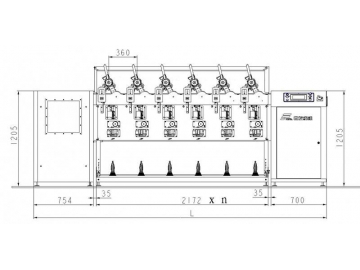

Spindle arrangement: single side arrangement

Transmission device: single spindle

Spindle number of each pitch: 6

Spindle number/pitch: minimally 6/1 maximally 60/10

Spindle gauge: 360mm

Pitch: 2172 mm

Bobbin shape: cylindrical bobbin or conical bobbin of which the max taper angle is 3°30' for filament; cylindrical bobbin or conical bobbin of which the max taper angle is 5°57' for short fiber

Minimum diameter of the bare bobbin: inner diameter: 43mm; outer diameter: 47mm

Bare bobbin length: 170-290mm

Max diameter of the roll: 280mm

Traverse length: 25-250 mm

Machine speed: maximally 2200m/min (the craft speed is decided by the yarn and some other craft parameters)

Power source frequency: 50/60Hz

Installed power of each spindle: 0.25kW

Practical power consumption of each spindle: 0.05-0.10 kW (according to different craft)

Dust proof and cooling fan power: 2.2kW

Travelling blower (optional) power: 1.1kw

Air temperature: 10-40℃

Relative humidity (no condensate water): 50%-75%

- The BW32 cone yarn precision winding machine uses electronic yarn guide technology, which carries out precision and digital winding. This allows it to be used to produce precise packaging to satisfy different packaging requirements. For example, the yarn winding density on the bobbin is at its maximum, or the yarn winding length is limited at its maximum volume.

- All the winding parameters can be easily modified, stored and searched on the control screen, which is much easier than methods used on a traditional winding machine.

- The winding machine functions are managed on the control terminal installed inside the control box on the machine head. The bobbin's craft parameters are set via the control terminal. The terminal also carries out real time monitoring and data statistics during the production.

- The spindles can be set integrally and operated independently, allowing users to carry out flexible operation and simultaneous processing of different yarn types on a single machine.

- The winding machine has a length control and diameter testing device, allowing it to carry out winding length and roll diameter testing. It can also achieve an auto stop at a fixed length or diameter.

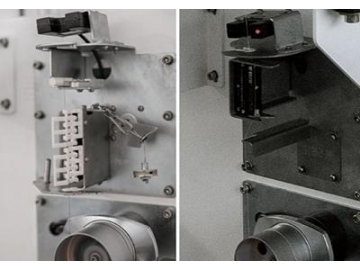

- Online tension control system: optional for production of dyeing bobbin

- Oiling device: optional for rewinding requiring oiling

- Air suction cleaning device: optional during the processing of short fiber

- Gate grid tensioner: optional during the processing of filament

- Chuck type tensioner: optional during the processing of short fiber

| Pitch number | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Spindle number | 6 | 12 | 18 | 24 | 30 | 36 | 42 | 48 | 54 | 60 |

| Total length (mm) | 3668 | 5826 | 7986 | 10146 | 12306 | 14466 | 16626 | 18786 | 20946 | 23106 |