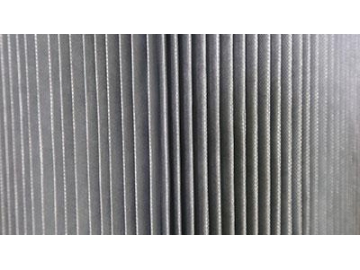

Antistatic Cartridge Filter Element

Anti-static cartridge filter elements have a layer of conductive aluminum film plated on the surface of polyester fiber, which will effectively conduct electricity to avoid electric sparks produced by static electricity. These filter elements are suitable for applications that are at risk of explosion, because they will eliminate an electric charge produced by the friction found in synthetic mediums in the petrochemical industry.

Anti-static non-woven fabric filter elements work at temperatures below 135℃ and are tolerant to numerous chemicals, making them ideal for use in powder recovery. They are often used in environmental dust removal equipment, coating equipment, powder spraying equipment, polishing dust removal equipment and dust collecting equipment.

| Size (O.D. × I.D.) | O.D. 325mm×I.D. 215mm (220mm), Accept nonstandard customization and sample orders |

| Size (Height) | 600mm, 660mm, 900mm, 1200mm |

| Material | Anti-static polyester |

| Dirt holding capacity | 240g/m2 |

| Thickness | 0.6mm |

| Bearing back flushing pressure | 5-6kg |

| Airflow rate | 125Lm2/sec |

| Powder recovery rate | 99.2% |

| Filter precision | 8-10μm |

| Collecting efficiency/Filter precision | 2-3μm/56.8% 99.7%/8μm |

| Top and bottom end cap | Zinc electroplating |

| Inside frame diamond mesh | Zinc electroplating |

| Bearing temperature | ≤135℃ |

| Tensile strength | Kgt5cm MD130.2 CD56.2 |

| Air resistance | 2.68mbar When airflow is 40cm/s |

- Polyester fiber surface is plated with aluminum to avoid electric sparks caused by static electricity.

- It is easy to clean dust off the filter element, with a dust cleaning rate that is 50 to 60% higher than common filter elements.

- The filter elements adopt inside and outside reinforcement with no end cap dropping.

- There is connecting insulating adhesive inside, which effectively holds the iron mesh and non-woven fabric apart in order to avoid wear and tear on the non-woven fabric.

- The end caps and filter support cage are all treated by zinc electroplating, ensuring they are rust resistant.

- Filter elements feature an M-shaped folding with folding depth of 100mm and width of 1.8m, thus enlarging the filtration area of a single filter element.

You can directly choose from the above displayed antistatic cartridge filter elements. If you have any specific demands for filter element size, surface treatment method and other aspects, please contact us in time and Xin Huan Bao will provide you with custom service for antistatic cartridge filter elements.

If you want to customize other types of filter elements such as flame retardant fiber filtration, back flushing filter elements and pleated filter elements, you can enter custom page, see custom instructions and provide us with necessary information.