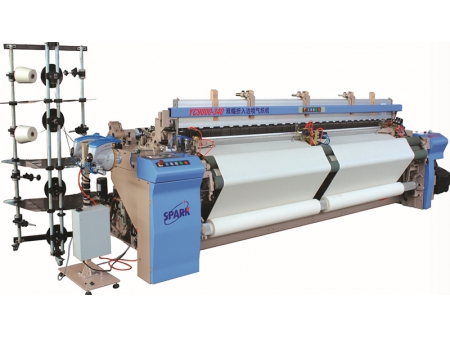

Air-jet Terry Towel Loom

RFJA33 air-jet terry towel loom features a comfortable and easy operation. It improves operator comfort through the height reduction of the warp end position (During the loom leveling, the warp passes the heald wire and the pathway from the heald wire eye to the cloth-fell from the top surface of the back-rest.) An easy operation of all basic functions is achieved through use of an HD colorful touch screen human-computer interface.

Reed width (cm)

Nominal reed width: 190cm, 210 cm, 230 cm, 260 cm, 280 cm, 340 cm

Effective reed width: 0~60cm subtracted from the nominal reed width (190-230cm)

0~60cm subtracted from the nominal reed width (more than 190-260cm)

Weft

Weft selection: select freely from 4, 6 colors

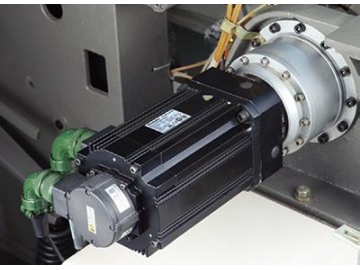

1. Direct drive motor

RFJA33 air-jet terry towel loom features a direct drive motor that is capable of generating a high output torsional movement when the loom starts. This improves the beating strength of the first spindle. This loom also features an electromagnetic brake with a large torque to improve the loom braking performance, thus preventing any fabric flaws caused by the loom stopping. This also improves overall fabric quality.

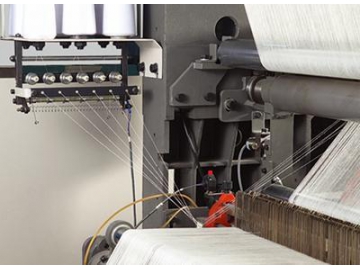

2. Loop motion

The servo motor can precisely control the loop motion, achieve a simple adjustment and improve the terry quality. This loom is easily able to produce terry cloth in a variety of different lengths and type, including pique terry and wavy terry, among others. The loop motions can achieve a 3-7 weft automatic loop notion, and switching significantly improves the towel's pattern flexibility. Operators can control the terry length and production period via the display screen, which makes switching between different patterns easy.

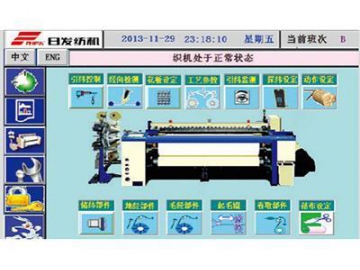

3. Computer control system

RFJA33 air jet loom is equipped with human computer interface keyboard for the display of a variety of information, including the running state, cause of failure, weaving craft parameters and the loom settings. The input of various data is easy simply through the use of function keys, and various parameter settings can be stored in the loom for long periods of time with the use of a memory card. Users can choose Chinese or English operation interfaces according to their requirements.

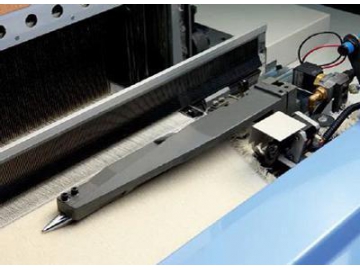

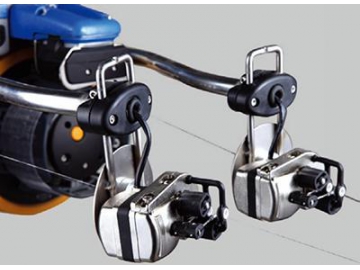

4. Double probe weft feeler

The weft feeler uses a double probe to detect the normal short weft and weft bending. It can also detect the break weft and ultra long weft, all in order to prevent any errors. The probe also features an excellent pollution resistance, making detection stable and reliable.

5. Upper temple

Because this loom uses a temple with an upward inclination, it is easy to adjust and cover the temple.

6. Integrated gas path system

All the components of the gas path system within the entire machine are integrated onto a single operation panel that takes up very little space. This makes operation easy, and saves space occupied by the loom.

7. Precise loop motion

1) The tension setting for the precise loop motion system is accomplished at the terminals. The wool warp tension is monitored by the electronic linear transducer, and all real time feedback parameters will be managed and monitored by a high performance CPU microprocessor. These feedback parameters, as well as the take-up and let off parameters, achieve synchronous weaving.

2) The loom is equipped with a monitor system in order to achieve real time detection of the towel length and density of various wefts.

3) With the design of a highly sensitive towel tension control mechanism swing beam and light support, this loom can produce both minimum and most regular terry heights, even when using the most delicate yarn types.

8. Energy saving

Because the loom is equipped with a gas valve between the 2 auxiliary nozzles and the air movement distance is shorter, gas consumption is 10% less than other traditional equipment.

| Item | Specification | |

| Power mechanism | Starting method and power of motor | Driven by super start motor |

| Super start motor: 3.7KW (dobby shedding motion) | ||

| Super start motor: 5.5KW (jacquard shedding motion) | ||

| Running operation | Direct stop location control carried out by electromagnetic brake | |

| Button switch double hand operation | ||

| Beating mechanism | Four-bar links beating (narrow reed width ), six bar links beating (wide reed width) | |

| Weft insertion mechanism | Main nozzle and auxiliary nozzle combination (optional extensive nozzle) | |

| Use profile reed (optional ABS weft brake) | ||

| Auxiliary main nozzle | ||

| Shedding mechanism | Positive cam shedding motion: 20 heald frames in maximum | |

| Jacquard shedding motion | ||

| Let off mechanism | Electronic control continuous positive let off | |

| Ground warp flange diameter: φ800, up warp flange diameter: φ1000 (Ground warp flange diameter: φ914, φ1000, up warp flange diameter: φ1250) | ||

| Take-up mechanism | Electronic take up | |

| Weft density range: 25~300 weft/inch | ||

| Max cloth roller diameter: φ600mm (built in roller) | ||

| Yarn supply frame | Floor stand 8 yarn cone (4 spray), floor stand 12 yarn cone (6 spray) | |

| Loop motion | Servo loop motion: loop pile motion by fabric movement. 3-7 weft automatic loop motion and function switching control. | |

| Ferry length: set freely from 0-28mm. The spacing accuracy can be up to 0.1mm. | ||

| Selvage mechanism | Mechanical leno selvage mechanism | |

| Yarn end treatment | Waste selvage twisting drum type | |

| Weft cutter | Mechanical weft cutter on the left and electronic weft cutter on the right | |

| Accumulator | Vibration accumulator | |

| Lubrication | Bath oil type for the main drive and automatic centralized oil supply | |

| Stop motion | Weft stop: photoelectric weft feeler with double probe | |

| Warp stop: double row and double list electric contact type warp stop device | ||

| Others: automatic stop for leno yarn and waste selvage yarn break | ||

| Stop motion display: the control panel can show the reason of stop motion with multifunctional 4 color stop motion display. | ||

| Automatic function | Control: multifunctional micro computer control system which has the functions of parameter setting, control, monitor, self diagnosis and human computer intelligent interface | |

| Slow inching carried out by frequency converter (normal and reverse inching turning) | ||

| Other: output terminal of the monitor | ||

| Automatic control of spray | ||

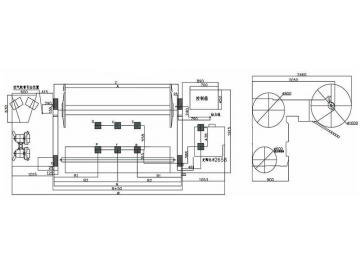

| Reed width (inch) | A | B | C | W | B1 | B2 |

| 190 | 1900 | 2460 | 2385 | 4578 | - | - |

| 210 | 2100 | 2660 | 2585 | 4778 | - | 1330 |

| 230 | 2300 | 2860 | 2785 | 4978 | - | 1430 |

| 260 | 2600 | 3160 | 3085 | 5278 | 1090 | - |

| 280 | 2800 | 3360 | 3285 | 5478 | 1090 | - |

| 340 | 3400 | 3960 | 3885 | 6078 | 1090 | - |

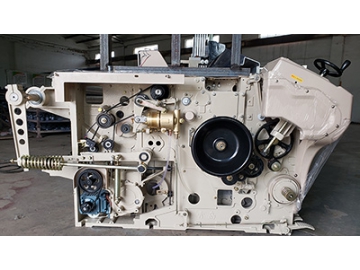

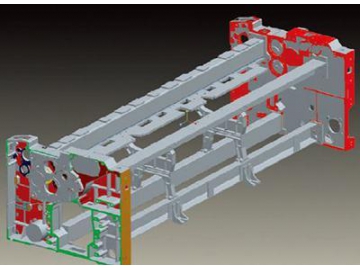

Machine rack

Machine rack Supporting device at the center of the rock shaft

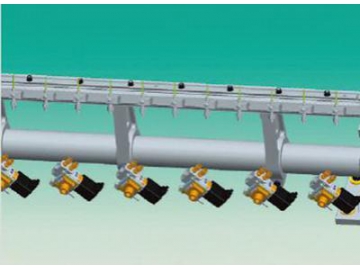

Supporting device at the center of the rock shaft  Vibration Permanent Magnetism electric drum accumulator

Vibration Permanent Magnetism electric drum accumulator