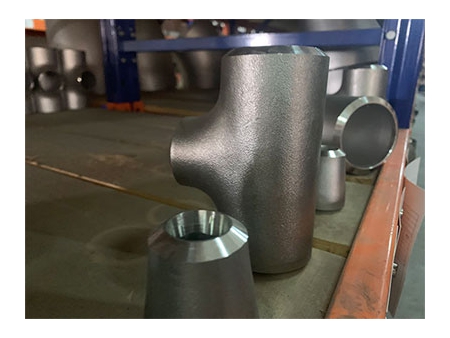

Other Metal Pipe Fittings

Besides stainless steel, carbon steel and alloy steel, our company will also make use of other materials to manufacture pipe fittings. Our customers are allowed to select among duplex stainless steel, super duplex stainless steel, nickel base alloy, Monel alloy, titanium steel, zirconium steel, copper steel, aluminium steel, etc. based on their requirements for the product proprieties.

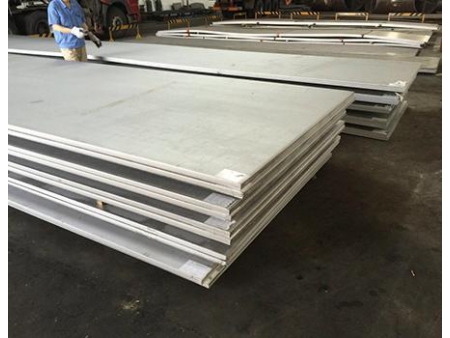

- Dual-phase steel plate

Duplex stainless steel and super duplex stainless steel feature the same good properties of austenitic and ferritic stainless steel, such as high ductile brittle transition temperature (DBTT) of 475 degrees Celsius, high thermal conductivity and super great plasticity.

Meanwhile, duplex stainless also excels ferritic type in terms of plasticity, toughness, intergranular corrosion resistance and welding performance. Compared with austenitic stainless steel, it also has greater strength and greater capacity of withstanding intergranular corrosion and chloride stress corrosion cracking.

Titanium steel pipe

Titanium steel pipe

With excellent punch properties, titanium steel adapts well to different welding processes. The weld joint could reserve 90 percent strength of the base metal. Titanium steel pipe has strong ability to withstand the corrosion caused by chloride, sulfide and ammonia. In addition, it also excels aluminium, stainless steel, nickle base alloy in terms of resistance to corrosion by seawater.

Meanwhile, it is also the great properties of titanium steel that brings about great difficulty on the cutting and machining process. In addition, it is easy to introduce impurities into the titanium material during heating process. Hence, the production process will be very complex and great skills and advanced technology are required.

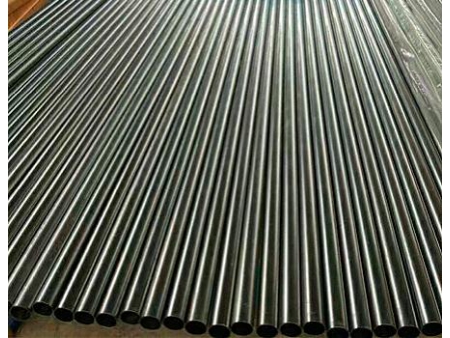

Zirconium steel pipe

Zirconium steel pipe

As a rare metal, zirconium has melting point as high as 1800 degrees. The melting point of zirconium oxide even reaches 2700 degrees. In addition, it also features astonishing corrosion resistance and super great hardness and strength. It exhibits great advantages over titanium in every aspect. With so many great characteristics, it has been widely applied in areas such as aerospace, military, nuclear reaction and atomic energy.

With relatively high price, these special materials are mainly applied in engineering projects in special areas. They are made with standard dimensions (wall thickness) in most of the time. In generally, we make use of seamless steel pipes to produce pipe fittings through cold forming process.

When large size pipe fittings are required, we will switch to steel plate. At this time, production process selected would be compression forming by mold. If the wall thickness required is normal, cold press forming will be conducted on the raw material directly. If the wall thickness is larger than the outer diameter, then heating is required before compression forming.

Once formed, these pipe fittings will go through heat treatment first. Then nondestructive inspection and dimension measurement will be done for the surface. If qualified, the surface will be processed further and be imprinted. All these procedures are conducted strictly in accordance with technical indexes provided by customers.

Material Type- ASTM A815 WPS31803, WPS32205

- ASTM A815 WPS32750, WPS32760

- ASTM B127/163/164/165 N04400

- ASTM B163/166/168 N06600

- ASTM B443/444/446/564 N06625

- ASTM B163/407/408/409 N08800, N08810

- ASTM B574/575/619/622 N010276

- Titanium: TA2, TA10, TC1-TC9

- Zirconium: Zr-1, Zr-3, Zr-5, Zr-0