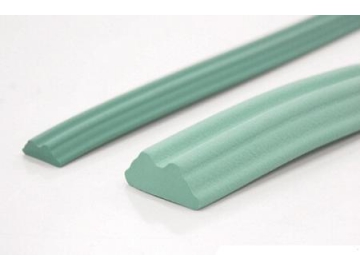

Rubber Screens

Request a Quote

The rubber screens are made of raw rubber with canvas, nylon, steel plate or steel wire as skeleton. Its manufacturing principle is similar to rubber belting but with two differences: increased thickness and 10-15 times molding pressure.

The rubber screens feature high abrasion resistance as good as PU, high efficiency, noise abatement and excellent impact resistance. Due to the long distance between discharge mouth and screening surface, the rubber screens are advantageous for screening large granular materials (>50 mm).

Advantages compared to metal screens

- Plugging problems eliminated.

- Longer service life.

- 10-45% higher screening efficiency.

- 50-70% lighter weight.

- 10-15dB lower noise.

- 50-60% shorter installation time.

- 35-55% lower total cost.

Advantages of rubber screens

Vibrating screens in ferrous metal mine, non-ferrous metal mine or non-metal mine.

- Modular rubber screen panels are easy to install, shorten maintenance time and save labor cost.

- Standard module size 305*610, applicable to model 3673, 3661, 2460, 2160, 1836 screening machines to achieve standardization of parts.

- The conventional rubber screen needs to change the whole screen if a part is worn. Duratech rubber screen supports modular replacement to save cost and extend the screen life to more than one year.

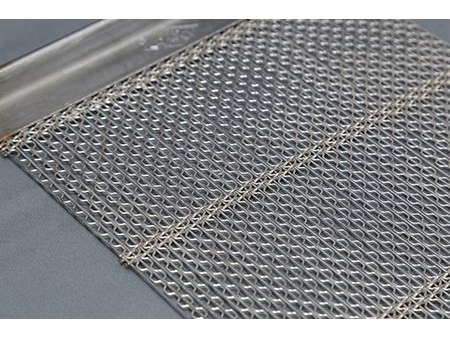

- Alternate slot design increases opening area and improves screening efficiency.

- Light screen weight of 4.5kg. Reduce the screening machine's operating load.

- Opening area on the flexible rubber screen can shake and vibrate to reduce plugging.

- The best solution to two-layer vibrating screen: the first layer uses impact-resistant rubber screen the second layer adopts the abrasion-resistant PU screen.

Related products

Send Message

Most Recent

More

Other Products

Videos