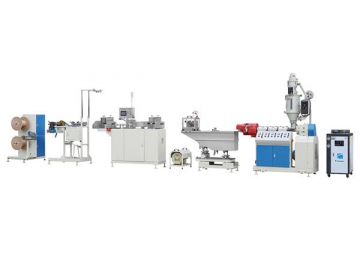

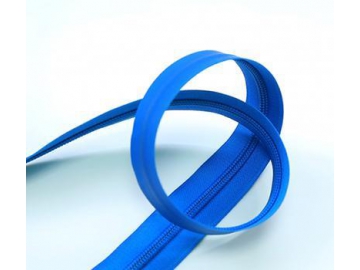

JL45B Zipper Extruder, Zipper Tape Extrusion Line

JL45B plastic extrusion line can produce various types of zipper profiles by changing its mould, which can be designed according to your samples or specific requirements. It is our basic and standard type of zipper profile extruders, its quality and reliability are proven by time and have earned market recognition. If you are looking for an economic and high performance

Parameters| Model | JL45B |

| Material | LDPE,PP |

| Production Speed | 10-50 |

| Zipper Width | 3-50mm |

| Thickness of zipper | 0.3-2.2mm |

| Diameter of screw | 45mm |

| Draw ratio of screw | 25:1 |

| Power of Main Motor | 5.5kW |

| Power of the auxiliary motor | 1.1kW |

| Power of dehydration and drying | 2kW |

| Zipper winding unit | 1.1kW |

| Heater Power | 6.8kW |

| Total Power | 22kW |

| Overall Dimension | 9350*1300*2200mm |

Production Line Composition

This extrusion line consists of Chiller, main extrusion part, die head, automatic filter changer system, die plate, water tank (form the zipper at constant temperature), dehydrating system and air-drying unit with Vacuum blower, zipper traction part, auto zipper-closing part and zipper rewinding unit. The die plate of zipper can be designed according to customers’ sample or drawing.

Optional Device

Die plates for different types of zipper

Teeth Device on zipper Closing unit

Teeth Device on zipper traction unit

- The mould of our JL-45A zipper extruder adopts the advanced 45 degree extrusion, and it is easy and convenient to be assembled and disassembled from the machine.

- Our zipper extruder is equipped with the stainless steel storage tank.

- According to the special demand of the material flow rate in the process of producing zippers, the charging barrel and screw of our equipment are made from high quality alloy steel, which is chrome plated, resulting in strong resistance to abrasive, extreme heat and deformation.

- Our zipper extruder's motors adopt Panasonic frequency converters, well-known hard surface reducer and the torque motor reeling machine, which ensures our zipper equipment's stable performance and high production capacity.